My local water utility recently contacted our home to inform us they were turning the water off from noon to 6:00 p.m. to repair a newly discovered water leak. This situation made me think about water loss, specifically how long the water line had been leaking, how many gallons of treated water was lost, and how a utility keeps up with water loss. This Iron Strong Blog describes the various components of a Water Loss Control Plan (WLCP) and the importance Ductile iron pipe (DI pipe) plays in an overall water management strategy.

WHAT IS WATER LOSS?

You’ve heard the expression, "Water is life.” Water plays a significant role in sustaining environments, economies, and communities worldwide. Its presence attracts and retains, while its absence disperses and limits. Communities require water systems that meet drinking, sanitizing, production, and firefighting needs.

Water loss refers to the amount of water lost or unaccounted for within a water distribution system. Water losses can be either:

- Apparent losses due to meter inaccuracies, including both customer meters and plant meters which record system demand, unreported use by entities for firefighting training or actual firefighting use, unmetered irrigation of public facilities, unmetered use by street sweepers or like equipment, etc., or unauthorized consumption;

- Actual losses are due to water service line breaks, leakage on mains and hydrants/laterals, or storage

From an economic standpoint, a water utility must be proactive regarding water loss because utilities cannot bill for lost treated potable water. Utilities must implement a strategy from a sustainability aspect because there is only so much water to go around.

HOW BIG IS THE WATER LOSS PROBLEM IN THE U.S.?

According to the American Society of Civil Engineers, the following are some statistics related to water loss in our country:

- The United States uses 42 billion gallons of water a day

- Around 80% of drinking water comes from surface waters such as rivers, lakes, reservoirs, and oceans, with the remaining 20% from groundwater aquifers

- Drinking water is delivered via one million miles of pipes nationwide

- Every day, nearly 6 billion gallons of treated drinking water are lost

WHAT ARE THE COMPONENTS OF A WATER LOSS CONTROL PLAN?

A Water Loss Control Plan (WLCP) is a comprehensive strategy designed to identify, quantify, and minimize water losses within a water system. The following represents the general components of a typical plan.

Assessing Water Loss:

The initial step in developing a WLCP is thoroughly assessing or auditing the existing water distribution system. This audit includes:

- Evaluating infrastructure conditions

- Reviewing metering practices

- Analyzing consumption patterns

By understanding the system's current state, utilities can identify areas of concern and prioritize actions for maximum impact.

Leakage Management:

Leakage is a significant contributor to water loss, and an effective WLCP incorporates strategies for leakage management. This involves:

- Identifying and addressing leakage hotspots through regular inspections

- Deploying advanced leak detection technologies

- Prioritizing repairs based on severity and potential impact

Implementing proactive maintenance programs and investing in infrastructure upgrades can minimize leakage and extend the lifespan of distribution assets.

Pressure Management:

Maintaining optimal pressure within the distribution system is crucial to minimize leakage. Excessive pressure can lead to pipe failures and increased leakage rates. A WLCP emphasizes pressure management strategies such as:

- Installing pressure-reducing valves

- Implementing pressure control zones

- Monitoring pressure profiles

By optimizing pressure levels, utilities can reduce leakage and improve the overall efficiency of the system.

Metering and Monitoring:

Accurate and reliable metering is essential for detecting and addressing unauthorized consumption and meter inaccuracies. WLCPs include initiatives to upgrade or replace outdated meters with advanced metering technologies, such as smart meters, which provide real-time consumption data and detect anomalies. Regular meter testing and calibration ensure accurate billing and assist in identifying areas with potential water losses.

Non-Revenue Water Management:

Non-revenue water (NRW) refers to water that is produced and lost before reaching paying customers. Water utilities focus on reducing NRW through targeted measures. These may include:

- Identifying and rectifying illegal connections

- Encouraging responsible water use through public awareness campaigns

- Implementing demand management strategies like water conservation programs

- Communication with water-using entities such as fire departments, parks, etc., to ensure they are reporting non-metered water use

NRW reduction leads to improved revenue generation and a more sustainable water supply.

Data Management and Analysis:

Water utilities rely on data-driven decision-making to develop effective WLCPs. Advanced data management systems facilitate the collection, storage, and analysis of water-related data, including:

- Consumption patterns

- Leak reports

- Infrastructure conditions

Analyzing this data helps identify trends, establish benchmarks, and measure the effectiveness of water loss reduction efforts. Utilities can also employ predictive analytics to anticipate potential areas of water loss and take proactive measures.

Training and Capacity Building:

A successful WLCP requires a well-trained workforce with the necessary skills and knowledge. Utilities invest in training programs to enhance staff expertise in:

- Leakage detection

- Infrastructure assessment

- Metering technologies

- Data analysis.

By fostering a culture of awareness and competence, utilities can ensure the effective execution and continuous improvement of water loss reduction strategies.

Stakeholder Engagement:

Water utilities collaborate with various stakeholders to achieve water loss reduction goals, including government agencies, industry partners, and community groups. Engaging stakeholders fosters collective responsibility and facilitates information sharing, promoting more effective water management practices. Public participation and transparency initiatives help educate consumers about water conservation and encourage active involvement in reducing water losses.

WHAT IMPORTANCE DOES DUCTILE IRON PLAY IN A WATER LOSS CONTROL PLAN?

Now that we've covered the components of a Water Loss Control Plan, let’s discuss how the properties of Ductile iron pipe (DI pipe) can help a utility reduce its water loss.

Detecting and Locating Leaks:

Significant leaks are generally easier to find because a utility can detect them through visualization or gauges /metering. But minor leaks are usually more challenging to locate and can go undetected for years, costing a utility a substantial amount of water loss and lost revenue. One of the best ways of finding water leaks is acoustic detection.

How does acoustic detection work?

Acoustic detection equipment works by transmitting pulsations and using a pick-up stick to identify and differentiate the various sound patterns of water flow. Water leaking through a buried pipe produces a specific high-frequency to low-frequency sound that acoustic detectors can easily pick up.

Iron material (DI pipe) will amplify the frequency of water leaks up to 10 times longer than other pipe materials, thus making locating a water leak from DI pipe much more straightforward. As almost everyone knows in the waterworks industry, finding water leaks is often the most challenging component of any WLCP.

Repair and Replacement of Infrastructure:

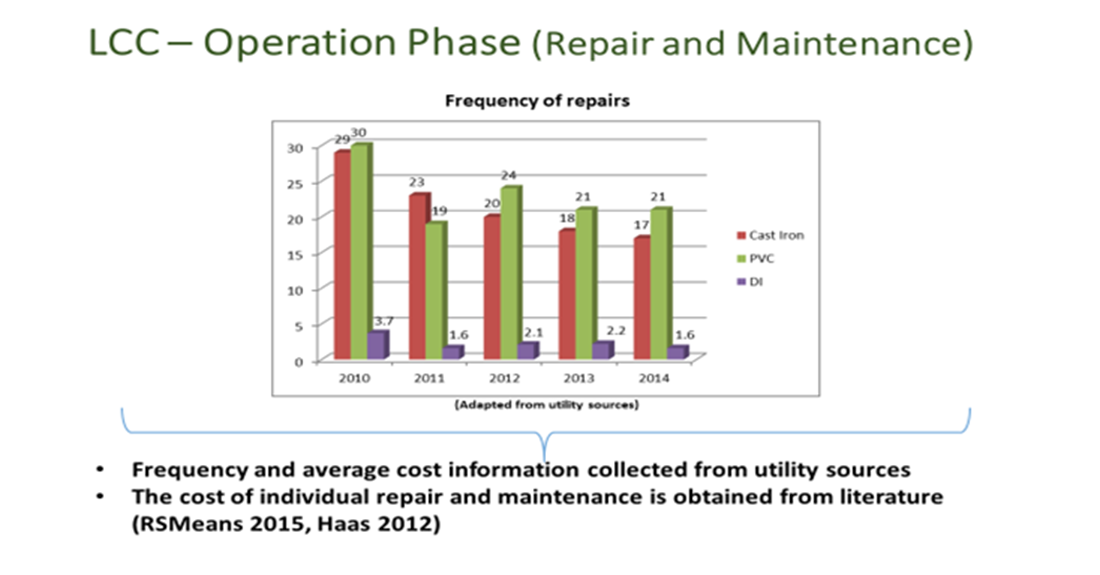

Another area where Ductile iron pipe can help reduce water loss is the repair and replacement of pipelines. DI pipe is highly durable and reliable. These characteristics allow utilities to spend less time and effort maintaining and replacing pipe compared to other pipeline materials.

Thus, a water utility will have more money and resources to apply to other WLCP aspects. This claim is highlighted by a University of Michigan report titled, A Framework to Evaluate the Life Cycle Costs and Environmental Impacts of Water Pipelines (See Below). The study interviewed different utilities across the United States and found that DI pipe significantly reduces maintenance cycles compared to other pipeline materials.

The strength and durability of Ductile iron pipe provide another advantage when reducing water loss — its service life. When DI pipe is installed in proper applications, the utility can expect a service life of at least 100 years. That is up to twice as long as other pipeline materials. The longer service life means a utility can extend capital funds twice as long as other pipe materials.

These savings can be utilized in other system parts, including their WLCP. The longer service life of DI pipe is proven through various references such as AWWA’s Buried No Longer Report, the previously mentioned University of Michigan Report, and DIPRA’s Century Club recognition.

CONCLUSION

A comprehensive Water Loss Control Plan is designed to identify, quantify, and minimize water losses. Incorporating the components discussed in this blog will allow water utilities to implement a program to determine their water use and loss, prioritize water projects and operational changes, and continuously improve their water loss control program.

In addition, using long-lasting, durable, and reliable Ductile iron pipe can assist with keeping water rates low for customers and ensure future generations have access to clean, safe water by reducing the 6 billion gallons a day of lost treated water.

Other informative Iron Strong Blogs related to this topic and written by my colleague Roy Mundy, P.E., ENV SP, ASSOC. DBIA are:

- Unaccounted for Water – The Phantom of the Forgotten City

- Considering Resiliency When Choosing Pipe Materials

- Why Is Safe Yield Important to the Water Utility?

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, contact your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.