Over the last few years, the world has been affected by many things, and the ongoing repercussions are still seen today. These effects also impacted the waterworks industry and the handling of pipe stock and pipe yards. During that time, we witnessed delays in the supply chain and extended lead times. Manufacturers and distributors were keen on getting pipe in their yards and holding more quantities and sizes than ever. Pipe and gaskets then began to sit for longer periods. Due to the durable nature of Ductile iron pipe (DI pipe), sitting idle did not affect the product, but lack of use for pipe gaskets was more apparent.

During a recent visit to a job site, a McWane Ductile associate encountered a project that was delayed for various reasons. Among the neglected materials were ductile iron gaskets, which were left exposed to the elements and visibly deteriorated. This situation necessitated the replacement of the 30” gaskets to prevent any waterline issues. The question arises: what if a visit to the job site and a thorough yard audit had not taken place? In this #IronStrong Blog, I will share some essential tips, techniques, and recommendations for maintaining an efficient and complaint-free Ductile iron pipe yard for distributors, municipalities, and job sites.

Safety First – In a Distributor Yard or On the Job Site

- Always keep safety in mind. This is true not only with pipe deliveries but every single day from open to close at a distributor yard or job site. Let’s list some key tips:

- Wear proper PPE, including high-visibility garments and fall protection if required when handling, loading, and off-loading pipe. See my colleague Dan Flaig's helpful blog here: Handling Ductile Iron – From Truck to Trench

- Check your materials for visual defects or damage.

- Count the products you received and compare them to the Bill of Lading (BOL). Many times, trucks carry 2-3 purchase orders with multiple stops. Ensure what you ordered is what you are getting.

- Separate your products in an organized fashion—separate Tyton Joint from TR Flex. Keep the Protecto 401 sewer pipe in a location separate from the water pipe. Keep gauged full-length pipes separate for field-cut pieces if needed.

- Make sure you have the right materials to do the job, including all proper PPE (personal protective equipment) and the correct size equipment to handle the load.

- See my colleague Josh Baker’s helpful blog here: Receiving Ductile Iron Pipe – What to Know Before You Let the Truck Go

What Should I Look for When Conducting a Pipe Audit?

- Ensure proper dunnage and chocks are used for pipe storage. This includes chocks for all trucks and other equipment. What is Dunnage, you ask? – “In construction, dunnage is often scrap wood or disposable manufactured material intended for placement on the ground to raise construction materials and allow access for forklifts and slings for hoisting. Dunnage can also protect pipe and other materials from the elements." (Wikipedia). Below is a picture of how McWane Ductile utilizes wood dunnage and chocks to ensure the secure storage and handling of DI pipe.

- Follow height, weight, and industry recommendations. These recommendations matter when distributors deliver stock loads to contractors or municipalities. The following video helps explain the proper recommendations in detail. How Much Ductile Iron Pipe Can Fit on One Truck?

- While Ductile iron pipe is stocked and stored in your yard, keep in mind that surface oxidation may occur. The biggest concerns would be the cement lining and stock rotation.

- Forklifts move around yards every day, and accidents can happen. Damage to the pipe while in-stock is possible, due to improper handling or impact from a collision. Walk your yards to check the bell end, plain end, and along the barrel to ensure no noticeable damage has occurred. Manufacturers entrust distributors to take proper steps to ensure the end user receives quality material.

- Distributors should walk the yards while visually scanning and inspecting the quality of the materials. McWane Ductile Sales Representatives should also walk the distributors' yards.

- You might have or see some returned P401 that is a few years old and outside its usable shelf life. Ensure all pipes in your yard are sellable.

What Are Some Key Items Regarding Gaskets to be Aware Of?

Gaskets must be properly cared for prior to installation by all who handle and store them. The manufacturer, distributor, and contractor should follow the tips below to ensure gasket performance in the future. Some industries use the method known as FIFO (First In, First Out). The primary industry that uses this term is food. This process involves constantly rotating old to new and always ensuring the stock levels remain as fresh as possible. For example, if you received some new refrigerated foods but have some leftovers that have been there for a few days, remove what has been sitting and replace them in the back of the back of the fridge with newly purchased items. Then, finish stocking the refrigerator. The item closest to the front is the oldest that needs to be consumed before expiring or going bad.

- Continue to rotate the stock of gaskets and ensure newly received gaskets go to the back of wherever they are stored. FIFO

- This technique will ensure that the best quality gaskets are always shipped for installation, resulting in a successful installation.

- Always consider and know there is a shelf life to gaskets and all rubber types with varying factors contributing.

- Exposure to the sun can reduce gasket performance exponentially, so they should be kept indoors, inside a job site conex, or inside a pipe (if for short periods).

- Keep gaskets at or above 40 degrees F.

- Keep "specialty" gaskets separated from generic gaskets at all times. Specialty Gaskets

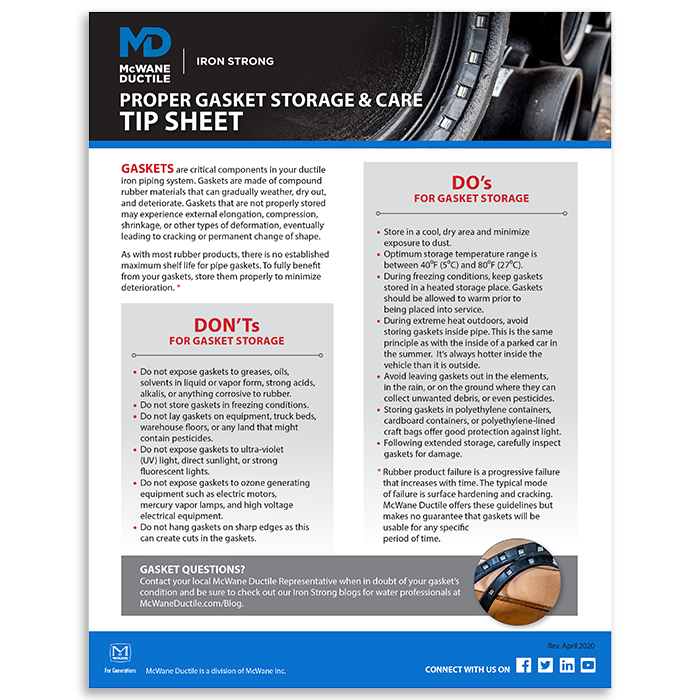

- Take a look at our gasket tip sheet. If possible, follow the DOs and DO N'Ts at all times. A great tip for distributors is to have printed copies at will-call counters when contractors come to pick up our Ductile iron pipe.

Take care of critical components of your pipeline system! Avoid the harmful effects of improper gasket storage with our free and handy tip sheet.

DOWNLOAD NOW

What Should I Know About Lube Audits?

Proper choice of pipe lubrication and lube application are crucial in installing Ductile iron pipe. Not all lube is the same. Be sure to send the correct lube with the right kind of pipe. Example: Many projects have Ductile Iron, Concrete, and PVC pipes at the job site at the same time. All three use and specify different lube types.

- For any new installation, only supply and use unopened lube.

- Distributors should carry multiple sizes of lube. The contractor may need to finish a few joints or install thousands of feet. Proper stock of all sizes makes you a one-stop shop for contractors. Some common sizes to have on hand are quart and gallon. Other sizes are available upon request.

- Utilize the FIFO method for pipe lube when stocking at a distributor's warehouse or job site.

- McWane Ductile will supply these directly on any pipe shipment leaving our locations. Currently, McWane Ductile only approves using the following pipe lubricants:

- Phoenix™ Lube

- Black Swan®

- NO-OX-ID® Lubricant (Available upon request for subaqueous installation)

What are some Distributor Tips & Strategies?

For this blog, I met with some distributors. I asked them to answer a few questions and provide (Standard Operating Procedures (SOPs), tips, and simple tactics to ensure a successful business operation. These distributors have numerous employees who have been in the waterworks industry for many years and have abundant knowledge.

Mike Reyff, Branch Manager, and Abel Megui, Warehouse/Ops manager, Core & Main, Phoenix, AZ

What tips/tricks/SOPs do you follow for proper gasket storage?

- We constantly rotate our stock, especially due to the warm Arizona climate. Gaskets are stored inside our warehouse to limit rubber degradation.

- What tips/tricks/SOPs do you follow when receiving a pipe delivery to your yard? Core and Main maintain a zone of safety when unloading all trucks. Our zone consists of a virtual 20-foot safe area while operating equipment. 10' to either side and require drivers to remain in their vehicles.

- How do you educate contractors or municipalities on proper pipe, gasket, and lube handling and storage once they have been sold to them? Many of our customers rely on the expertise provided at Core and Main. Our sales and operations team provides the customer with resources to ensure they have the correct material for whatever projects they are working on. We rely on the expertise of our vendors to guide us on best practices for storage.

Collin Stout, Inside Sales – Waterworks, Scholzen’s Products, St George, UT

What tips/techniques/SOPs do you follow for proper gasket storage?

- Properly storing Ductile iron pipe gaskets is crucial to maintaining their integrity and performance.

- Ensure the storage area is clean, dry, and free from contaminants like dirt, dust, oil, or chemicals.

- Maintain a consistent temperature in the storage area. Extreme temperatures can affect the material properties of the gaskets.

- Store gaskets away from direct sunlight to prevent UV degradation.

- Implement a first-in, first-out (FIFO) inventory system to ensure older gaskets are used first.

What tips/ techniques /SOPs do you follow when receiving a pipe delivery to your yard?

- When receiving ductile iron pipe as a distributor, it is essential to handle the material carefully and ensure it meets quality standards.

- Thoroughly inspect the shipment upon arrival. Check for any visible damage to the pipes themselves. Document any discrepancies or damages for potential claims with the supplier or carrier.

- Count the number of pipes received and compare it to the order to ensure accuracy. Verify that the received pipes match the specifications (e.g., diameter, length, wall thickness) specified in the purchase order.

- Check the surface of the pipes for any defects, such as scratches, dents, or corrosion.

- Ensure the pipes are handled carefully during unloading and storage to prevent physical damage.

- If discrepancies or concerns are identified during the inspection, promptly communicate them to the manufacturer to initiate resolution procedures.

You can Ensure Good Product and Educate Others

Would you rather have a rotten apple or a fresh, delicious apple? We often assume the people buying pipe and gasket know how to store and install the product, so you must ask yourself, “How can I educate contractors or municipalities on proper pipe, gasket, lube handling, and storage?”

You have been provided valuable tips to ensure you take the information and keep your stock of apples, pipes, gaskets, and lube the freshest. I challenge you to take this back to your local branches and job sites and audit your own practices to determine the health of your pipe yard. Again, ask yourself, “What have I learned in this blog so I can ensure a safe, efficient, and complaint-free Ductile iron pipe yard?"

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is equipped with the expertise to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.