It's hard to believe summer is ending, especially because summertime is one of my favorite seasons of the year! I love floating in the water with the sun on my face, relaxing. However, for some, this floating sensation brings anxiety. The same force that allows us to float in the water affects all materials, including pipe.

This physical force is called buoyancy. Buoyancy calculations are extremely important for those building ships and boats. We don’t really think about it when dealing with buried pipe, but those same principles and forces apply. Good for boats, but bad for buried pipe.

Buoyancy Force Equation

Buoyancy is the tendency for fluid to exert a supporting force on a body placed in the fluid. As stated below, this force is called a "buoyant force" and is defined by Archimedes' principle.

A body in a fluid, whether floating or submerged, is acted on by a buoyant force equal to the weight of the fluid displaced. The buoyant force acts vertically upward through the centroid of the displaced volume and can be defined by the equation below:

Fb = ϒf Vd

Where:

Fb = buoyant force, lb

ϒf = specific weight of the fluid, lbs/cubic ft

Vd = displaced volume of fluid, cubic ft

An object with an average specific weight less than that of the fluid will tend to float, while an object with an exact average weight greater than that of the fluid will tend to sink. When a body is floating freely, it displaces a sufficient volume of fluid to simply balance its own weight or buoyant equilibrium.

For example, a water balloon will not sink or float in a large pool. The water balloon is in static equilibrium and only has two forces acting on it (the weight due to gravity and the buoyancy force).

Pipe Buoyancy

All pipe material is affected by buoyancy. Ductile iron's specific weight is greater than that of water. Therefore, Ductile iron pipe full of water will not float. However, if the pipe is partially full or empty, buoyancy may be a factor. A study of the existing groundwater table in the area needs to be completed.

If the groundwater levels are below the bottom of the pipe, then buoyancy is not an issue. If groundwater is above the bottom of the pipe, then buoyancy calculations must be performed. The following information will be needed to determine buoyancy:

- Weight of the pipe

- Weight of soil

Now, you can calculate the buoyant force if we assume the specific weight of the water displaced is 62.4 lbs/cubic foot. If the buoyant force is less than the resisting force of the pipe in the ground, then the pipe will not float, and no further action is required. However, if the buoyant force is greater than the resisting force, movement or changes to the pipe will need to be considered.

For Ductile iron pipe, simply increasing the pipe thickness and thus increasing the weight of resistant force may be the solution. Another solution could be to change the backfill specifications to a more structural type backfill involving compacted material around the pipe. As long as a pipe has an average specific weight greater than the fluid it displaces, it will tend to sink.

Eighteen-and twenty-foot laying lengths of push-on joint Ductile iron pipe in the following sizes and classes will not float in water (62.4 lb/ft3) even when they are unlined and entirely empty: 3-, 4-, and 6-inch diameter in all pressure and thickness classes; 8-inch diameter Special Thickness Class 52 and greater; I0-inch diameter Special Thickness Class 54 and greater; and 12-inch diameter Special Thickness Class 56.

Also, Ductile iron ball joint pipe in small sizes, generally 4-inch through 16-inch, will not float in water when empty. Buoyancy data for each type of ball joint pipe can be obtained from the manufacturer. Please refer to Ductile Iron Pipe Research Association’s (DIPRA) Buoyancy Effects on Ductile Iron Pipe for further information and more details.

Alternative materials such as HDPE and PVC have innate buoyancy issues regardless of diameter. They all float and therefore require specific attention (permanent anchoring, such as concrete structures around them) during initial planning and installation.

For more information on the differences and advantages of using Ductile iron pipe over HDPE and PVC, see these helpful blogs by my colleagues:

- HDPE and DI Pipe – Difference that Matter – A Comparative Narrative, by Ken Rickvalsky

- What Are the Advantages of Ductile Iron Pipe Over PVC Pipe? By Jerry Regula

Pipe Installation When Buoyancy is a Concern

When installing water mains, sanitary sewer force mains, or gravity sewer lines on or below a riverbed, on flood plains, adjacent to rivers/creeks, or swamps, buoyancy needs to be considered in your design. The amount of cover or weight of soil/water on top of the pipe contributes significantly to whether the pipe will float. These calculations, including examples, are discussed in detail in DIPRA's Buoyancy Effects on Ductile Iron Pipe.

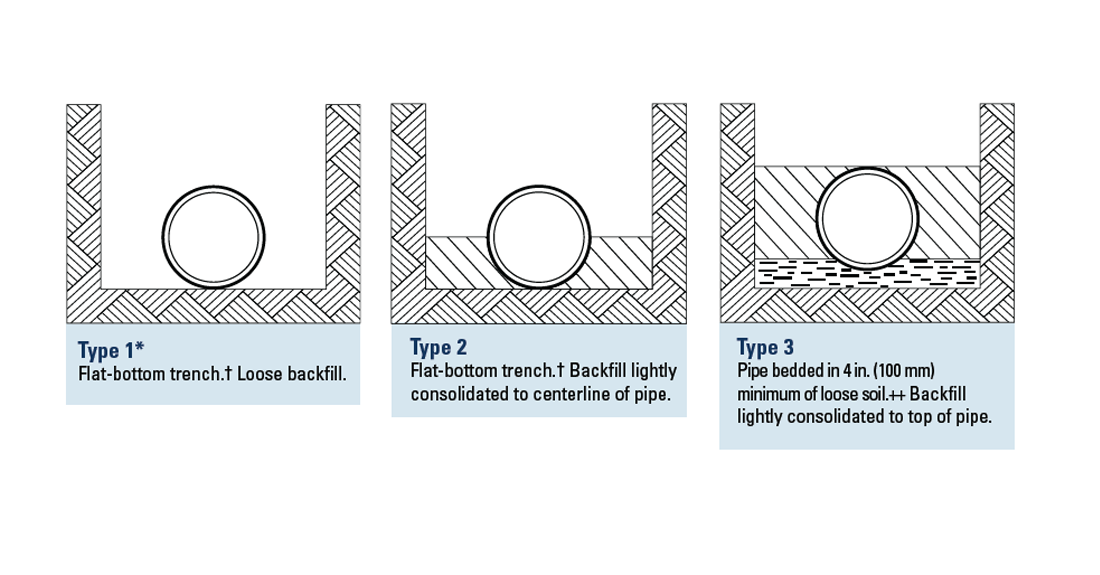

When installing a pipe in an open trench, another influence on the buoyancy calculation is the trench backfill type as shown in the diagrams below with types 1 or 2 being normal trench type for normal ductile iron pipe installation.

When buoyancy is a concern, types 4 or 5 should be used to improve the resultant force of buoyancy. Using type 4 or 5 will also decrease the pipe thickness needed and would somewhat preclude other soils with tight compactability and minimum void spaces to allow less infiltration for water buoyancy, such as consolidated clays. In addition, it is recommended to use restrained pipe, such as McWane Ductile’s TR Flex® versus unrestrained options like Tyton® Joint Pipe. Using TR Flex or pipe allows for more flexibility after installation.

If flooding is a concern for the buried pipe, additional anchors over the pipe can be used. Various types of anchoring systems can be implemented, but this will require design and approval by the engineer of record and manufacture.

Concrete is commonly used to anchor pipes when buoyancy is an issue. Keep in mind, concrete and grout exist as fluids before hydration and have a specific weight of approximately 130 to 150 pounds per cubic foot. This weight creates a buoyant force more than twice that of water. For this reason, when liquid concrete is poured entirely around any pipe, the pipe tends to rise. This effect can be eliminated by either pouring the concrete in lifts and allowing the concrete to hydrate and become solid before the next lift is poured, or by using tie-downs on the pipe.

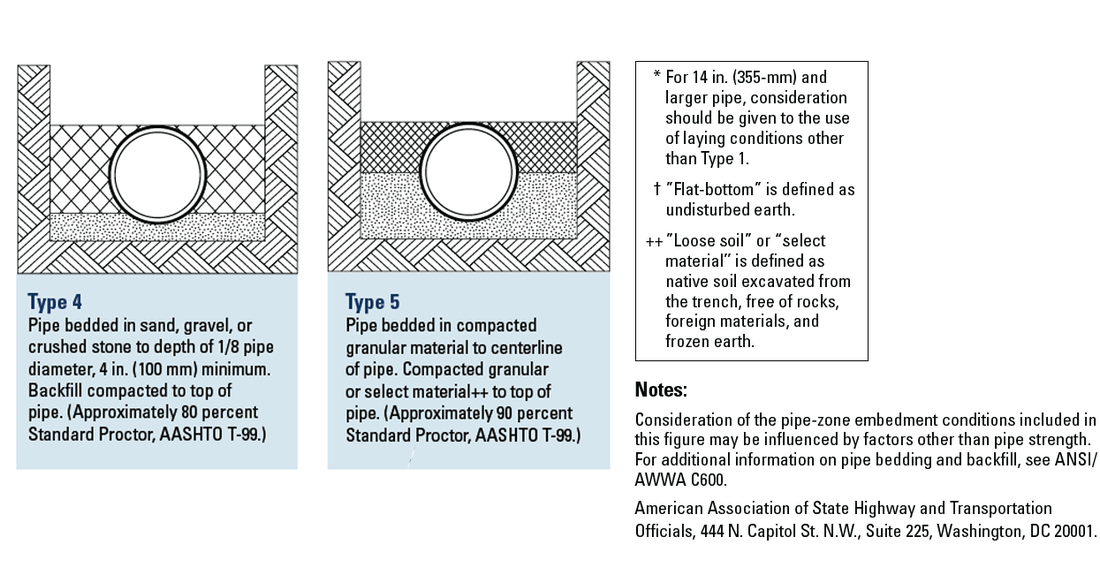

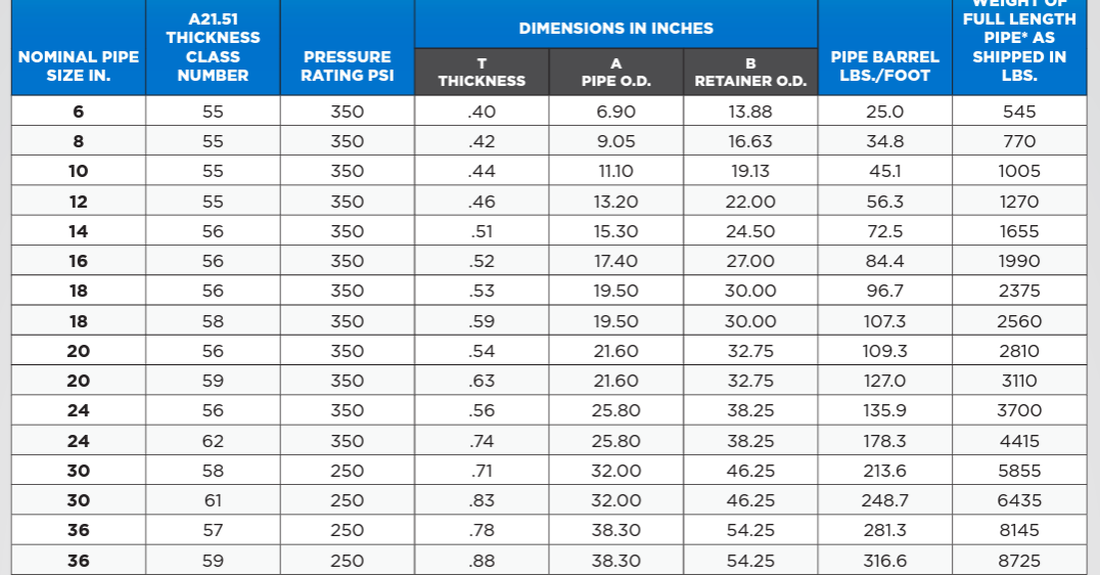

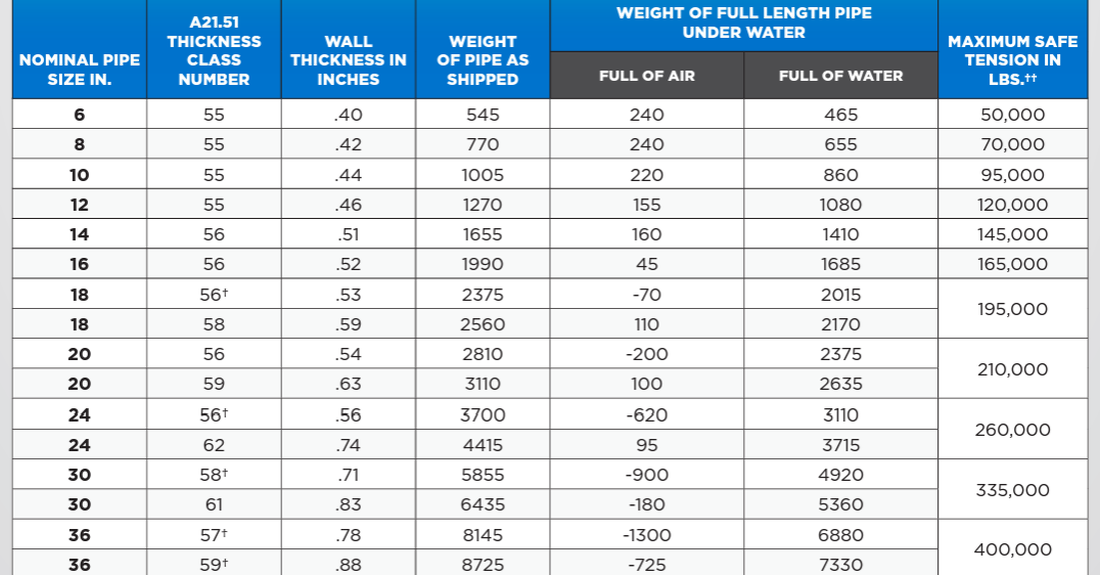

River crossings present special challenges for coping with the buoyancy of the pipe being installed. These projects will use Ball and Socket Joint pipe for maximum joint deflection. Recall that Ball and Socket Joint pipe 16-inches and smaller will sink in water, while pipe 18-inches or larger will typically float. The figure below from McWane Ductile shows the selection of pipe classification and sizes:

Ball and Socket Details and Dimensions

Buoyancy of Ball and Socket

For two stories that provide great details of river crossings using Ductile iron pipe, see the Iron Strong blogs by my colleagues listed below:

- Another River to Cross: Milo, Maine, The Town of Three Rivers, by Ken Rickvalsky

- What Are Common Installation Methods for Ball and Socket River Crossing Pipe and How Is It Installed? by Jeff Houser

Buoyancy can also affect some pipelines during trench installations, due to heavy rains before backfilling or high water tables. Completing backfilling at an early stage (and prior to testing as recommended in ANSI/AWWA C600) is particularly effective in preventing empty pipes from floating. After installation, it is advised to fill the pipes with water as soon as possible for maximum security.

Conclusion

When buoyancy is a potential issue in the design of your pipeline, you must consider pipe classification and trench type, especially if the pipe could be empty at any time after installation. While it is important to understand how your pipe will react when displacing water, your design can also include elements like anchors and tie-downs to achieve a successful installation.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.