YOU ASK, WE ANSWER! McWane Ductile’s technical engineering and informational presentations are valuable services we provide to water and wastewater professionals, just like you. Download the brochure below for a detailed list of available topics. Schedule your Lunch & Learn or even a Day of Water via our website at CONTACT US or call 800-800-6013.

We’re helping you Build Iron Strong Utilities for Generations!

-

Training Overview Brochure

Our technical staff consists of Registered Professional Engineers and NACE Certified Technicians with varied experience in the water and wastewater industry. From managing utilities to engineering to pipeline construction in the field, our team can support and assist your staff through virtual/live presentations and/or hands-on training. Contact us today!

-

Ductile 101 – Introduction to Ductile Iron Pipe

A comprehensive overview of the use of Ductile iron pipes for water and sewer applications. Attendees will garner insightful information from experienced professionals in the design, manufacture, installation, and service aspects of utility piping systems. Whatever your involvement is within those arenas, this presentation will show you what you think you know in an entirely different light, and without using a bunch of decimal points.

-

Ductile Iron Pipe Design – Internal & External

Attendees will be provided with information and resources to demonstrate why ductile iron pipe design calculations are the most conservative and reliable in the water and sewer industry. This presentation brings the math alive with easy to follow graphics and pictures, permitting quick assessments towards making your most effective pipeline materials selection.

-

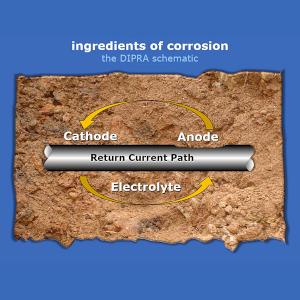

Basics of Corrosion & Protections for DI Pipe: Guided by the Updated DIPRA-Corrpro Design Decision Model™ (DDM™)

A balanced introduction to corrosive environments typically encountered by buried pipelines that will give attendees all the information they need to make an informed decision on utilizing available pipeline protection mechanisms, if needed. The decision-making process is guided by the Design Decision Model™ that was developed through decades of research and experience by DIPRA and Corrpro, two leading authorities on corrosion prevention across our industry.

-

Preliminary Engineering Report (PER) Template

This presentation covers the development and usage of a Preliminary Engineering Report (PER) to assist engineers and municipalities on the road to gaining USDA funding with data that justifies the use of DI pipe. Formatted to follow USDA Bulletin 1780-2 for Water & Waste Disposal Program, which involves analysis of alternate materials when preparing a PER.

-

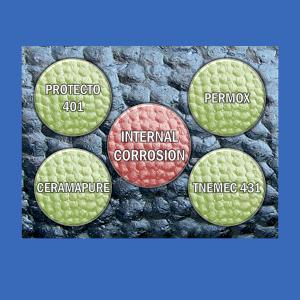

Internal Corrosion Prevention for DI Pipelines

Internal corrosion issues with Ductile iron pipe are a far different ballgame than external corrosion. External corrosion requires more ‘partners in crime’ to occur, and if just one of the required four components is missing, you won’t have corrosion. Internal corrosion can, and often is, simply the result of an aggressive fluid being transported within the pipeline.

-

Ductile Iron Pipe Restrained Joints – Basics and Design

The rubber gasket inside a Ductile iron (DI) pipe joint will keep it watertight against internal water pressures well above 1,000-psi yet that same gasket provides less than 100-psi worth of longitudinal resistance towards preventing joint separation in shallow or above-ground assemblies, hence the need for joints restrained by some additional mechanism. This presentation outlines how and why this occurs, through discussion of the forces, features, and functions of restrained joint DI pipe.

-

Bridges, Casings, and Joints … Oh My

This presentation examines the various joint systems of ductile iron pipe for use in aerial spans and installations through casings or other carrier pipes. Given the inherent strength and resiliency of ductile iron itself, Ductile iron pipes are perfectly suited for these types of installations where repetitive vibrations and other non-standard external forces can be encountered throughout the long life of the pipeline.

-

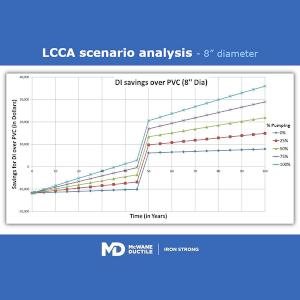

Sustainable Pipeline Design / Life Cycle Cost Analysis

The true value of a pipeline as an asset is based on several factors that impact its service life. This presentation explores the development of a model published by researchers from the University of Michigan in Ann Arbor that allows utilities and engineers to evaluate the total life cycle cost associated with a water transmission and distribution pipeline. Designed to compare ductile iron pipe (DI) versus polyvinyl chloride pipe (PVC), two of the most used pipe materials in the utility industry.

-

Envision™ and Ductile Iron Pipe

Pipelines are critical infrastructure around the world. With proper and responsible design principles applied pipelines can serve for more than 100 years establishing improved water, energy, and materials efficiencies for generations to come while having a minimal impact on the ecosystem. The Envision Rating System has often been described as the ASCE version of the highly-regarded Green Building Council LEED program, as evidenced in their general mission statement which declares “The purpose of Envision is to initiate a systemic change, to transform the way infrastructure is designed, built, and operated.”

-

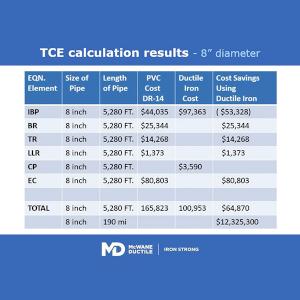

The Total Cost Equation of Pipeline Material Selection

Using the Total Cost Equation (TCE) to responsibly evaluate bid proposals for different pipeline materials often reveals the true cost differential between various pipeline materials involves much more than just the initial per foot bid price of the material itself. The TCE takes into consideration the real and respective factors directly related to the installation and future operation of a pipeline. The initial cost per foot of individual pipeline materials is many times deceiving. Design engineers and utility owners need to include several additional factors common to every pipeline in their materials selection assessment to best serve the utility and customers throughout the pipeline’s intended service life.

-

DI PIPE, PCCP, HDPE, PVC, STEEL & FRP A Comparative Narrative

Proper selection of pipeline materials for any utility system or portions thereof should be based on a wide variety of factors, not just price alone. Based on actual material properties and their related values, along with experiences through the years.

-

Horizontal Directional Drilling Using Ductile Iron Pipe

Sometimes, open-cut trench installation of a pipeline is not practical or even possible, such as across a waterway, a lake, an area of unstable ground, or where disruption of the roadway or other structures above the intended pipeline is unacceptable. This is where the innate strength, resiliency, and joint flexibility of ductile iron pipe pays huge dividends – through horizontal directional drilling (HDD) installation.

-

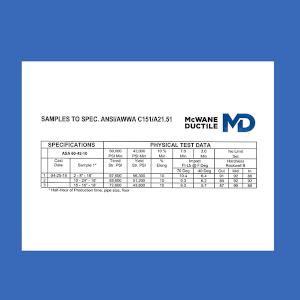

Ductile Iron Pipe Certifications – What They Provide

Old West stories of yore and so many movies of the past have shown persons biting down on a gold or silver coin to verify its authenticity. Surely there must be a better way, especially in the modern era, and there is - they are called mill certifications. In the case of ductile iron pipe these certifications capture all the pertinent quality assurance information related to a reliably small window of a pipe casting period. Complete traceability is achieved from the combination of integrally-cast markings upon every pipe, along with a time-stamped serial-coded production sticker attached to the exterior of each pipe at the bell end.

-

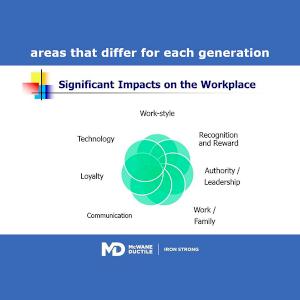

Generational Attitudes in the Utility Workplace

An internationally published research paper was constructed while the certified presenter of this MD Training Session, Roy Mundy PE, served full-time on the faculty of that accredited research institution. The values and attitudes of various generations that once were ordinary assumptions in society have in large measure been validated and delineated by this research project. Given these confirmations there are steps we can take to minimize the potentially conflicting value systems of people interacting within an organization, for the betterment of not only the organization but the individuals who comprise it as well.

-

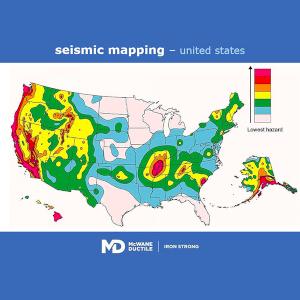

Seismic Resilience for Buried Pipelines

Original design incorporation or retrofitting for seismic resilience can play a major role in mitigating the potential damage of buried pipelines from seismic events or merely unstable soils. Seismic hazards include ground displacement, ground deformation, ground subsidence, or even liquefaction. Each of these hazards could devastate pipelines not adequately designed to tolerate them.