Why Use Horizontal Directional Drilling?

Those involved in the construction of water and wastewater pipelines are probably aware of the installation methodology of Horizontal Directional Drilling (HDD). HDD is a trenchless technique that provides an installation alternative offering several benefits over traditional open-cut installations. HDD can be implemented with minimal disruption to surface activities, requires less working space, and can be performed more quickly than open-cut methods. HDD can be used to install new pipelines or replace existing ones. Also, it can simplify or eliminate certain permitting processes.

Although there are currently no national standards regarding HDD installations of municipal underground infrastructure systems, HDD has seen a dramatic increase in recent years and is becoming more common for any pipe material. HDD may be the fastest-growing trenchless construction method today.

Key Pipeline Components in the Horizontal Directional Drilling Process

Flexible restrained joints are the key to the successful installation of Ductile iron pipe (DI pipe) for HDD. These joints result in a good distribution of thrust or pulling force around the bell and barrel and afford greater pulling forces than other pipe options. They also have a liberal allowable joint deflection with simultaneous joint restraint. They are quickly and easily assembled for "cartridge" installations, assembling the pipe one piece at a time during pullback, where there are limited easements or right-of-ways (ROWs).

Does the Use of Restrained Joint Gaskets in HDD Installation Meet the Criteria for These Key Components?

Quite simply, NO. Gripping push-on joint gaskets that utilize stainless-steel teeth, or locking segments, are not recommended for HDD installations. Joint deflection or relative rotation between two pipe sections during installation with these types of restrained joint gaskets could result in leakage or possible joint separation.

More simply put, deflections required in HDD installations can bend the joint in one direction, then see that direction change dramatically. This “one way, then another” can adversely affect the teeth on a restrained joint gasket, and as noted, cause failure or joint separation.

What is The Recommended Material to Be Used for Horizontal Directional Drilling?

Over the past years, engineers and utilities utilized HDPE as the default pipeline material for HDD. Unfortunately, many of the limiting qualities of HDPE have come to light in the industry. One glaring inadequacy is the "oxidative degradation" that occurs when using HDPE, caused by water treatment oxidants such as chlorine dioxide, which substantially decreases the pipe's estimated service life.

In another Iron Strong Blog by Roy Mundy, he investigates oxidative degradation and provides an answer to the question of, Should a Water Utility Manager Let System Infrastructure Dictate Water Treatment Methodology?

The product which meets and exceeds all the key component criteria for HDD is Ductile iron pipe, which has been used successfully in HDD lengths approaching 3,000 ft. DI pipe provides all the advantages listed below:

- A standard pressure rating of 350 psi.

- Great material strength for handling pull-back and external dead and live loading.

- Better distribution of thrust or pulling forces around the bell and barrel.

- Greater allowable pulling forces than other pipe options.

- Generous allowable joint deflections.

- Quick, easy joint assembly.

- “Cartridge” installation option for limited easements or ROWs.

- Performance capabilities are not impacted by elevated temperatures.

- DI pipe has material strength that does not creep or decrease with time.

- The pipe wall is impermeable to volatile hydrocarbons, minimizing the potential of water system contamination in the present or future.

- No significant residual bending stresses remain in the pipe after the pull-back that could adversely affect future serviceability, including tapping.

- No significant “recoil” and minimal pipe movement due to thermal expansion.

- Eliminates potential for shearing of tapped lateral outlets due to thermal expansion and contraction.

Due to the nature of HDD, a restrained joint system must be in place. Thus, TR-Flex® restrained joint pipe manufactured by McWane Ductile has been successfully used on many HDD projects across the country.

So, When Do I Use Restrained Joint Gaskets?

McWane Ductile Sure Stop 350® Gaskets have proven to be a superior method of restraining 3-inch to 24-inch DI pipe or fittings used in underground service within the utility industry. Installing a Sure Stop Gasket instantly achieves a boltless restraint system. In addition, the Sure Stop Gasket allows installers to cut pipe in the field quickly.

The installer does not need to prep the pipe's surface other than beveling the pipe's cut end required for any Push-On joint spigot end. Restraining the pipe joints with Sure Stop Gasket is simple and does not require any thrust blocks, bolts, clamps, rods, or retaining glands. See our blog “Sure Stop 350 Gaskets vs. TR Flex Pipe, Which Restraint is Best?" by David Bridge.

The restraint is provided by developing friction between pairs of high-strength stainless steel elements spaced around the gasket and the pipe's spigot. The stainless-steel element has sharp teeth on its inner surface and grips the pipe's spigot end as tension is applied, thus restraining the pipe.

The gasket works very similarly to a "Finger Trap Toy.” As most of us remember, the finger trap is a simple puzzle that traps the victim's fingers in both ends of a small cylinder woven from bamboo. The victim's initial reaction is to pull their fingers outward, but this only tightens the trap. The way to escape the trap is to push the ends toward the middle, which enlarges the openings and frees the fingers.

The tension put on the finger is similar to how the tension should be applied to the spigot end of the DI pipe, creating the friction required to keep the pipe together. The need for tension is why it is suggested that when using restrained joints gaskets in straight casing applications, the pipe should be pulled through and not pushed.

Pulling back on the Sure Stop Gasket causes the stainless-steel locking segments to engage the pipe, activating the restraint mechanism. If pulling back on the joint is not done, the line will "grow" when pressurized causing problems.

Although Sure Stop Gaskets are very effective in restraining pipeline fittings and appurtenances in most standard pipeline installations, as noted earlier, they should not be used in HDD operations.

Additionally, restrained joint gaskets are also not suitable for bridge crossings. Constant vibrations of bridge traffic transmitted to adjoining structures, in this case, a pipeline, will cause the "teeth" of the restrained joint gasket to either be deformed or possibly damage the pipe wall.

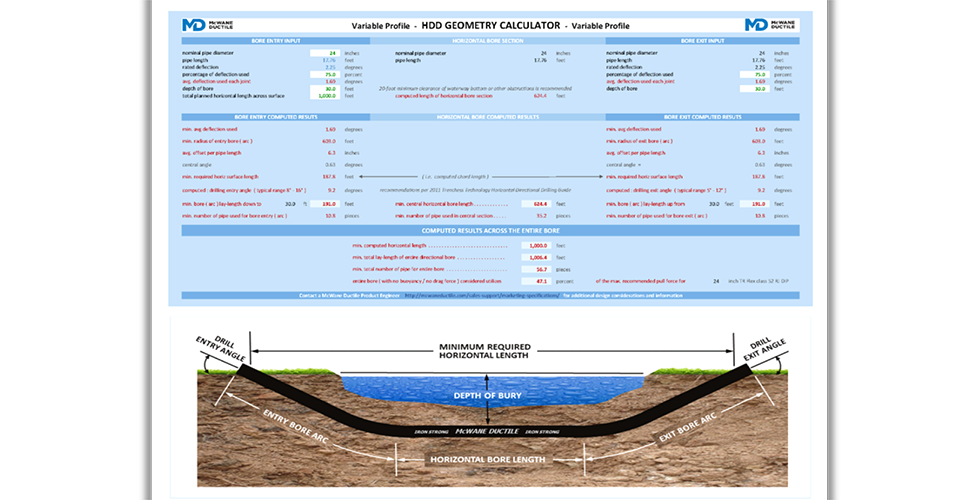

Pocket Engineer and HDD

The above figure shows a drill profile created from the Horizontal Directional Calculator on McWane’s Pocket Engineer App. This drill profile can easily be calculated and adjusted with just a few project-specific parameters entered within the calculator.

The Pocket Engineer is a free app that can be downloaded onto your computer, tablet, or smartphone. The application is extremely useful and contains information ranging from submittal information, contact information, the Pipe Economy book, and various calculators such as hydrotest, radius, thickness, volume, thrust restraint, and HDD geometry, to name a few. You can find the free app at pe.mcwane.com.

TR Flex® Restrained Joint Pipe ─ Made for HDD

McWane Ductile recommends the use of our TR-Flex Restrained Joint Pipe for Horizontal Directional Drilling applications. This product has been used extensively in HDD construction around the country, approaching 3,000 ft. in length.

Need Assistance with Your Waterworks Project?

If you have any questions or need additional information, please feel free to contact your local McWane Ductile Representative. Additionally, McWane Ductile’s Product Engineers provide extensive experience to our clients, assisting them with HDD design and construction. From design to installation, we take great pride in providing education and assistance to water professionals throughout the water and wastewater industry.