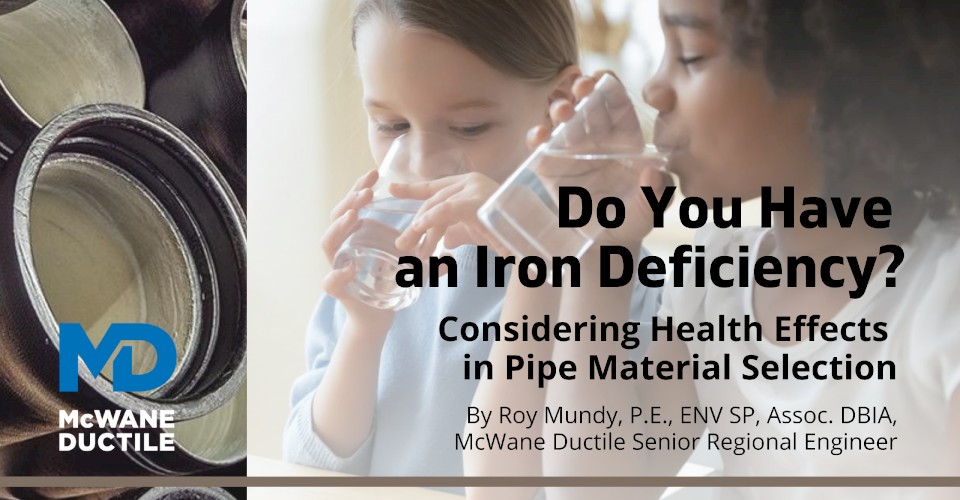

We in the United States are most fortunate, for the most part, to have access to safe, clean drinking water. Even when traveling, we are not hesitant to draw water from a hotel faucet to brush our teeth or even fill a glass to drink. This privilege is no accident.

Throughout the years, drinking water standards have continually gotten more stringent as technology, with applied science, has allowed for the identification of more possible contaminants at microscopic levels that could not be obtained in the past. Consequently, drinking water professionals have followed suit, educating themselves, and implementing a more sophisticated methodology to maintain these standards for their customers' safety.

However, even though much focus has been placed on treatment processes, many times, little focus is placed upon the drinking water system infrastructure that delivers the drinking water to the customer's residence, whether it be the water system transmission and distribution pipelines or the service line from the meter to the house.

Unfortunately, this came to light in Flint, Michigan, when it was found that a change in water treatment specifically affected existing lead service lines extending from the meter to the residence, creating higher than acceptable lead levels in the drinking water. Similarly, utilities have ceased to use asbestos cement pipe wherein a similar circumstance could occur if proper inhibitors are not utilized to prevent internal leaching of the product.

Therefore, should we consider the health effects of the pipeline materials delivering our drinking water? The answer is, of course, a resounding YES!

What We May Not Know – Now, Or in The Future

Pipelines that carry our safe drinking water traverse our communities underground in an environment that often is somewhat unknown or in surroundings that can change over time. Toxic substances in the ground, such as Volatile Organic Compounds (VOCs) or related chemicals can PERMEATE through the walls of certain plastic-based pipeline materials such as PVC (polyvinyl chloride), allowing these toxic chemicals to infiltrate the drinking water being transmitted.

This permeation CAN NOT OCCUR when utilizing Ductile iron pipe (DI pipe), now or in the future. This level of protection is a factor of safety that makes water professionals sleep better at night. For more on protecting water quality from permeation due to contaminated soils, see this Iron Strong Blog by my colleague, John Johnson.

Another unknown factor concerning drinking water infrastructure health effects can emanate from natural disasters such as wildfires. Studies have shown that toxic fumes are released from plastic-based waterline materials during wildfires, which in many cases, inhibit firefighters from entering an area to subdue the fire. The longer-lasting effects on water quality occur when these pipelines that have been subjected to such intense heat are placed back in service.

Let’s Look at The Inside-In

Many drinking water facilities throughout the country, including water tanks, water treatment plant basins, channels, etc. have been and are continuing to be constructed with innocuous Portland cement. The use of Portland cement has proven to be a very safe material when coming into contact with drinking water. This same material provides the lining for DI pipe, preventing build-up of mineral deposits as well as internal corrosion to the pipe wall. For more on tuberculation, see this helpful Iron Strong Blog by my colleague, Terry Lynch.

This tried-and-true internal lining system has been proven for more than a century, with NO substantiated report of resultant contamination from it or its components. This cement lining system has continued to maintain the integrity of the pipeline and the water quality of the drinking water distributed through it, even when needed water treatment oxidants are present. Unfortunately, this is not the case concerning some other plastic-based pipeline materials.

Documented cases throughout the country have shown that water treatment oxidants such as Chlorine Dioxide have significantly affected HDPE's service life through a process known as Oxidative Degradation. Additionally, the Centers for Disease Control and Prevention (CDC) has identified phthalates as affecting the reproductive system of laboratory animals. Although human health effects of exposure are unknown at this time, phthalates are widely used in polyvinyl chloride plastics.

Also of note is information in the book TROUBLED WATER—What's Wrong with What We Drink, authored by Seth M. Seigel. In his book, Mr. Seigel states: "One of the plastic pipes commonly used is polyvinyl chloride or PVC. PVC is derived from the chemical vinyl chloride.

During the PVC manufacturing process, it is common for some of the vinyl chlorides to fail when converted into plastic. The unconverted vinyl chloride remains embedded in the PVC. When the PVC comes into contact with water flowing through the pipe, some embedded vinyl chloride leaches into the water. When ingested, vinyl chloride can affect the central nervous system with symptoms including dizziness, headache, fatigue, and even loss of consciousness.”

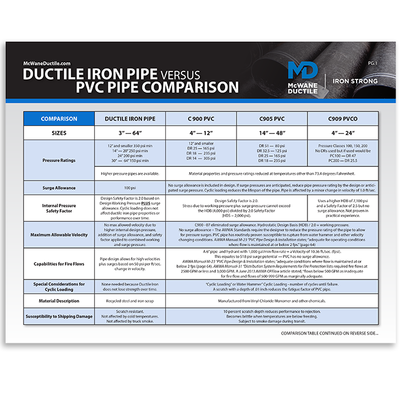

What are the differences and advantages of Ductile iron over PVC pipe? Many things! Use this handy comparison sheet to ensure you specify the safest, durable, and longest-lasting pipe for your next project.

The Forgotten City

Although up to 85 percent of the investment in a water utility's infrastructure is contained in the underground piping system, we often disregard this Forgotten City when it comes to strategic material selection due to its being "out of sight, out of mind." Many important factors should be reviewed when considering a pipeline project:

- Does the material I select provide hydraulic efficiency due to larger inside diameters?

- What is the estimated service-life of the material?

- What are the internal and external loading capabilities of the pipeline material?

- How easy is it to construct?

- Is there an extraneous cost when additional materials such as select bedding is required?

These factors and more clearly illustrate the superiority of using DI pipe. However, installing pipeline material that protects the integrity of the drinking water being transmitted with NO POTENTIAL OF NEGATIVELY AFFECTING THAT WATER QUALITY is priceless to the water utility professional.

Having been personally involved in catastrophic events during my career wherein the water quality of the drinking water of the system I managed could be effected, I fully appreciate the use of pipeline material such as Ductile iron pipe that has served the industry well over a century, leaving NO QUESTIONS to be asked regarding its effect on water quality.

We’re Here to Assist

For more detail on how these factors affect your pipeline design and considerations, contact your local McWane Ductile's Representative. We also have team members who have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

Sources:

- Seigel, Seth M., TROUBLED WATER—What's Wrong with What We Drink. New York: Thomas Dunne Books, 2019

- Toxicity of Building Materials, Pacheco-Torgal, Jalali, and Fucic

- Permeation of Organic Chemicals Through Plastic Water‐Supply Pipes, F. Goodfellow BEng, MRes, EngD (Graduate), S. K. Ouki Dlng, MSc, Ph.D., V. Murray MSc, FFOM, FRCP, FRCPath

- Ductile Iron Pipe Research Association - https://www.dipra.org/ductile-iron-pipe-resources/technical-publications/

- American Water Works Association (AWWA), Buried No Longer: Confronting America’s Water Infrastructure Challenge, 2015

- Design of Water Supply Pipe Networks, Swamee, and Sharma

- A Framework to Evaluate the Life Cycle Costs and Environmental Impacts of Water Pipelines, Thomas, Mantha, and Carol C. Menassa, University of Michigan