Although they may all look the same, every piece of ductile iron pipe is unique in its manufacture.

Each pipe has a set of identifying marks and labels that can assist the user in identifying the pipe itself as well as its intended use.

Each pipe also carries painted markings that will help the installer by providing information on the pipe length, identify pipe suitable for field cutting and assist in the proper installation of the material.

What are McWane Ductile's specific pipe markings?

All ductile iron pipe manufacturers use markings in a similar manner to assist customers in selecting the right material for the project. This includes verifying the material is suitable for the application intended (i.e. water or sewer) as well as adhering to the project requirements as stipulated by the owner/engineer for pipe class, lining, and exterior coating.

Because the colors used by each manufacturer may vary, we will explain how McWane Ductile applies these markings and describe their need and locations.

These markings or labels include:

- Spigot Stripes Used for Installation

- Green Paint Markings for “GFL” Pipe

- Blue Markings to Indicate “Zinc”

- Tick Marks Indicating Foundry Cuts to the Pipe

- The Pipe Label or Identification Sticker

- Special marking to Indicate Protecto 401™ Lined Pipe

- And the Indelible, Cast-in Information required by Standard

Spigot Stripes

These stripes are applied to the spigot or plain end (PE) of the pipe and provide both an alignment guide as well as a reference point to determine a pipe that is “FULLY HOMED" into the receiving bell.

Pipe manufactured as “Tyton® Joint,” such as manufactured by McWane Ductile and US Pipe, will have two even width stripes applied. These stripes also assist in the deflection of the pipe after assembly.

NOTE: Only after the pipe is fully homed should necessary deflection be taken.

To learn more about joint deflection and spigot stripes, check out our blog post with video by our Southern California District Manager, Carolyn Lopez: How Do Spigot Stripes Assist in the Assembly of Ductile Iron Pipe?

- Pro Tip: Pipe manufactured as Fastite Joint by American Ductile Iron Pipe will have only a single spigot stripe applied. Knowing this differentiation can provide a quick identifier to the user as to what joint they have and what gasket should be installed in the bell.

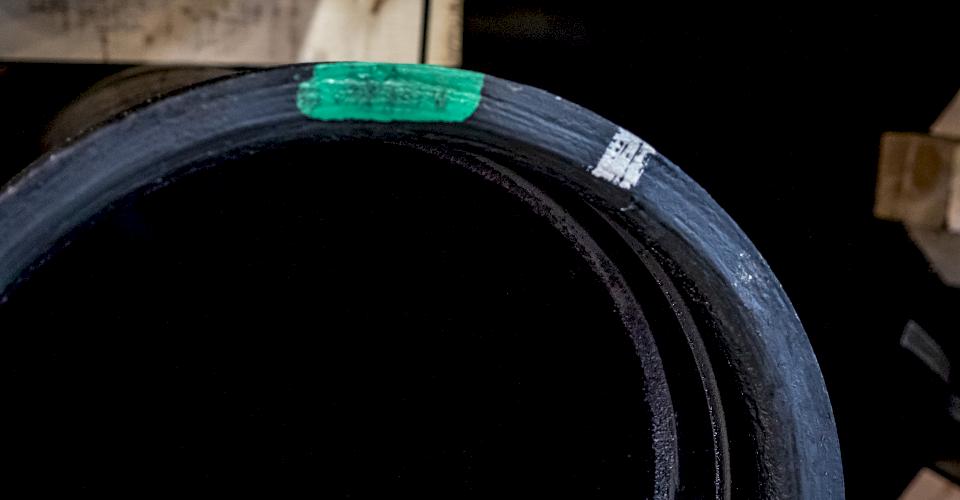

Green Paint for “Gauged Full Length”

Any pipe marked with green paint at the bell face will denote Gauged Full Length or “GFL” pipe.

This is typically only marked for sizes 14-inch and above and indicates that our quality assurance inspectors have determined that these pipes will be best suited for field cuts based on both the outside diameter measurements of the pipe as well as pipe ovality.

Note: pipe 14-inch and larger that are not marked with a "green bell” may also be field cut for assembly. The user would just need to perform some simple checks prior to cutting:

All pipe 12 inches and down would be considered “Gauged Full Length,” but our recommendation would be to measure the Outside Diameter of EVERY pipe prior to cutting and avoid cutting closer than 24 inches from the face of the bell without first measuring.A retainer gland can also be a useful tool to check pipe size and ovality prior to cutting. For more information on "How to Cut Ductile Iron Pipe to Length" check out our blog post and video by our sales representative, Jason Barnes.

Blue Paint for Zinc-Coated DI Pipe

Also marked on the bell face, the blue markings signify that the pipe has been received a coating of Zinc underneath the typical topcoat of the normal seal coat paint. The pipe typically carries a “Zinc” sticker, and this information will also be printed on the identification label.

Note: The use of Zinc coated DI pipe is recommended in areas where corrosion may be of concern. It is often recommended that these pipes also be encased in V-Bio® polyethylene encasement, too. For more information of the use of Zinc coated pipe, please consult our recent blog by McWane Regional Engineer, John Johnson on corrosion protection recommendations for Ductile iron pipe and the revised Design Decision Model (DDM) for buried pipelines.

Foundry Cuts

On some pipe, there may be visible white lines or “Tick” marks on the bell face. These marks denote that the pipe has been cut shorter than its standard nominal lay length at our facility. Each mark represents up to a 6-inch cut with the maximum allowed by ANSI/AWWA standard being 24 inches of trim which would be represented by four tick marks.

During a production run our quality staff will periodically take samples from the plain end of a pipe as required by the Standard for physical testing. They may also find it appropriate to trim a pipe due to the condition of the plain end following manufacturing. As this is a crucial part of the joint make-up, our group is very particular with inspecting these cuts and re-beveling the plain end to facilitate smooth assembly in the field.

Identification Stickers

Typically located near the bell end of the pipe, the sticker describes all the pertinent information concerning the pipe including:

- Pipe Size (Diameter)

- Pipe Class

- Joint

- Lining(s) and Coating

- Cast Date

- The appropriate accreditations our products carry

The labels may vary depending upon the type and size of pipe ordered as well as the foundry where it was manufactured.

Special “Red” Marking to Indicate Protecto 401™ Lined Pipe

McWane utilizes Protecto 401 as its primary inside lining for sewer applications. As with other linings used in this application, it is not suitable for use in potable water distribution.

Therefore, to make sure that this specially lined pipe does not get inadvertently installed for water use, it is clearly marked with a red primer coating of Protecto 401 on both the bell and spigot ends. Often, the words “For Sewer Use Only” are also marked on the pipe.

Cast-in Information required by Standard

By requirements of the ANSI/AWWA C151/A21.51 Standard, all ductile iron pipe must have the following information cast-in or stamped on the pipe in clearly legible markings on or near the bell: the manufacturers mark, country where cast, year of production, and the letters “DI” or “DUCTILE”. The pipe diameter is also marked on the pipe in this manner.

Lastly, for some complex installations such as fully restrained joint projects with TR Flex® pipe and fittings, or perhaps a treatment plant project, it may be necessary to provide pipe that is Color Coded or has Mark Numbers applied to them. These markings will insure that the appropriate material is delivered and installed in a manner that corresponds with the line drawings or lay schedule that would have been developed for the project.

Final Thoughts

Hopefully this article has been helpful in providing a bit of insight on what the various markings on the pipe mean and why they are there. For additional information on pipe markings , please consult your local McWane Ductile Sales Representative.

Need Assistance With Your Waterworks Project?

McWane Ductile offers multiple services to our customers extending far beyond manufacturing DI pipe. From estimating to design, from production to installation, we take great pride in providing education and assistance to water professionals throughout the water industry.

Check out all our digital offerings: