Safe drinking water is essential for sustainable human life. Do you lie awake at night wondering if the water you are drinking is safe? Do you dream about the type of water lines used to transport water to your home or business?

If you are a design engineer or an official responsible for providing clean, safe water to hundreds, thousands, or even millions of residents, then you are most likely the type of person who dedicates a major portion of your time thinking about water quality.

Thankfully, there are entities and standards in place to ensure that products used in water transportation systems are of the utmost quality. In this blog, we’ll discuss the who, what, why, and how products designed to transport safe drinking water are monitored and tested during the manufacturing process at McWane Ductile to meet quality standards.

Quarterly UL Inspections

The Underwriters Laboratories (UL) symbol has been recognized for decades and can be found on numerous products around the globe. This agency was established in 1894 and is known for providing auditing and testing services to ensure goods and services meet specifications and standards such as ANSI/AWWA C150, C151, C153, C110, etc.

The UL symbol is found on ductile iron pipe and fittings. An important note is that ANSI/AWWA requirements for Ductile iron pipe and fittings are intended to produce products with a much higher pressure rating and more efficient operating system than alternative products.

On-site inspections are completed on a quarterly basis at the manufacturing facilities. Random samples are selected for dimensional verification. Production tests are monitored, and results are verified. Production gauges are also randomly selected for inspection and their calibration records are reviewed for conformance.

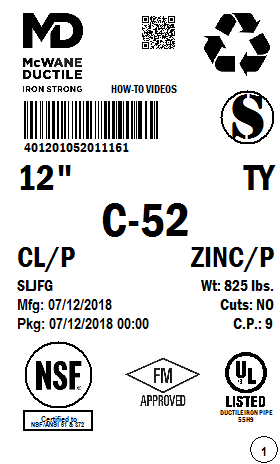

It is important to emphasize the use of independent auditing services. Municipalities will at times require independent auditing in their specifications. Did you know that verification of a company’s UL certification may be completed by logging on to the UL website and entering the company’s file number? That file number is found on each sticker applied to a McWane Ductile pipe.

Impartial Review - NSF 61

Founded in 1944, NSF is a public health and safety organization dedicated to protecting and improving global human health and ensuring products meet rigorous standards. NSF provides an impartial third-party review of material testing. All products that come in contact with drinking water must be NSF approved.

These products include:

On-site inspections are completed bi-annually at manufacturing facilities. Random samples are selected and sent for testing by a third-party test facility. Additionally, taste and odor tests are completed at each manufacturing facility on a monthly basis. Distilled water is used for all testing. Test results must indicate that there is no change in the color, taste, or odor of the water.

Tests are also completed for changes in water pH and Alkalinity. All McWane Ductile facilities use water-based seal coat and coatings. Water-based paints contain ZERO VOC’s(Volatile Organic Compounds). Zero VOC paints are applied to products that are primarily made of recycled materials. Now, that sounds like an excellent sustainable infrastructure project!

Get The Lead Out - NSF 372

In addition to the NSF 61 standard is the NSF 372. NSF 372 became effective in January of 2014. The Safe Water Drinking Act (SDWA) requires drinking water products to meet a weighted average of no more than 0.25 percent lead. This provides a third-party certification to ensure products meet the SDWA requirements.

We at McWane Ductile are proud to say that upon application of the new standard, no changes or alterations were required for our manufacturing process at any of our manufacturing facilities. As for other, alternative materials, numerous products were removed from service due to detrimental health issues.

On the contrary, cast and Ductile iron products have been used in operating systems for more than 200 years. More and more engineering professionals are applying Envision Sustainable Infrastructure principals to design processes. Consequently, Ductile iron products will likely be in use for many decades to come. Always inspect and never use products in drinking water applications that are not NSF approved.

Sticking to It – Pipe Identification Labels

The UL and NSF symbols are conveniently located on the identification stickers found on each piece of Ductile iron pipe. Additional information includes the following:

- Pipe Size

- Pipe Class

- Weight

- Lining

- Coating

There is also a QR Code. Scanning the QR code will provide you with additional product information.

Property Loss Prevention with FM Approved

FM (Factory Mutual) was established in 1835 and you see a product or service with the FM-approved certification mark, you’ll know it meets the highest property loss prevention product testing and certification standards.

McWane Ductile also provides FM-approved pipe. FM-approved pipe is typically used in fire suppression systems. McWane Ductile provides Push-On Joint and Mechanical Joint pipe in sizes 6-inch through 24-inch pipe at a 175 psi pressure rating.

At All Levels - ISO Certification

All McWane Ductile pipe manufacturing facilities are ISO 9001 certified. Once again, auditing by a third party is a requirement to achieve certification. ISO certification for a manufacturing facility begins with a focus on the customer. Striving to exceed customer expectations by understanding current and future needs is a must.

Leadership is also essential, as direction and purpose must be established at all levels. All levels begin with employees who see and touch the products, and then the process extends to top level management.

Continuous improvement of processes enables a company to continually move forward in a positive direction. A man once said, “If you are not moving forward, you are moving backward.” System control also extends to a supplier relationship. Mutual benefits are achieved when independent suppliers and the manufacturer work as a team.

Quality goals are achieved by providing documented work instructions, training, and calibration of all gauging and test equipment. It is easy to see that a great deal of work and effort must be put forth in order to seek ISO registration.

Summing It All Up

We have taken an in-depth look at a variety of stringent certifications and listings maintained by all McWane Ductile manufacturing facilities. So, what does all this really mean?

Residents and business owners have many things that garner attention such as family, jobs, daily routines, etc. Citizens should not have to be concerned with the quality and safety of the water they are consuming.

Rest assured, McWane Ductile continuously strives to meet all safety and quality certifications to ensure that the products used in water distribution systems are of the highest standard for safe drinking water. As always, we are Building Iron Strong Utilities for Generations!