Have you ever heard the saying, “To the man who only has a hammer in the tool kit, every problem looks like a nail? (Abraham Maslow)” In the water utility industry, some folks may feel this way when faced with a pipeline installation that must circumvent natural or human-made obstacles, especially water crossings. So, if going around or above is not an option, then what? How about below?

In today’s modern world, there are more tools available for installing water pipelines, such as open-trench/cut, above-grade pier systems, and Horizontal Directional Drilling (HDD). In this blog, we’ll discuss the benefits of using Ductile iron pipe (DI pipe) for HDD and provide some considerations and tips for your pipeline installation.

How is HDD Applied to Water Infrastructure?

HDD, also known as directional boring, was developed in the early 1960s and first used by the oil and gas industry for large-diameter, cross-country transmission pipeline installations. This process has evolved and revolutionized complex water crossings for pipelines that were initially completed using conventional dredging methods or rerouted over long distances and crossed at bridge locations.

Over the past 20 years, HDD has been approved and used for small-diameter gas distribution lines in urban and suburban areas, as well as for municipal water and telecommunication cable crossings at airports, highways, and waterways.

Benefits of Ductile Iron Pipe for HDD

DI Pipe has many attributes suited for the HDD, such as:

- Engineering professionals who use Envision, the Sustainable Infrastructure System, see the benefits of HDD, including cost savings and reduced environmental impact.

- The larger inside diameter of DI pipe compared to other pipe materials provides for increased volume while reducing energy (pumping) costs. Please refer to my colleague, Cole Mitcham's, blog for more information on how to save money on your electric bill by using DI pipe.

- If alternate materials require increased pipe size to compete with DI pipe, the drill hole diameter must also increase, resulting in higher drilling costs.

- The coefficient of thermal expansion for PVC and HDPE pipe is significant. When choosing a pipe material to drill with, the coefficient of thermal expansion must be considered, especially if a utility has a surface water source, such as a lake or river, to ensure that significant stress and strain do not damage alternate materials.

Also, TR FLEX® pipe manufactured by McWane Ductile comes in 18-foot nominal lengths. This length creates a tighter radius than pipes with 20-foot lengths. For example, a 12-inch pipe, 18 feet long, with a 5.00-degree deflection has a radius of 205 feet, while a 12-inch pipe, 20 feet long, with a 5.00-degree deflection has a radius of 230 feet.

Furthermore, McWane Ductile offers an HDD calculator on the McWane Pocket Engineer that provides a drilling profile to ensure the proposed pipe radius fits within your project parameters. The designer automatically adjusts this drill profile by inserting different project parameters, such as:

- Pipe entry and exit angles

- Horizontal drill length

- Depth under the barrier

Tips for Using Ductile Iron Pipe for HDD Design, Planning, and Pre-Construction

Some essential factors to consider before starting your HDD project are:

Preliminary Studies

- Sub-surface explorations

- Locating existing utilities and structures

- General inventory of existing landscape and vegetation along the proposed route

Legal Acquisitions

- Right-of-way and permits

- Permits for the removal of trees and shrubs

- Environmental permits

Public Relations

- How to keep property owners informed and up to date

- How and where to store materials and equipment

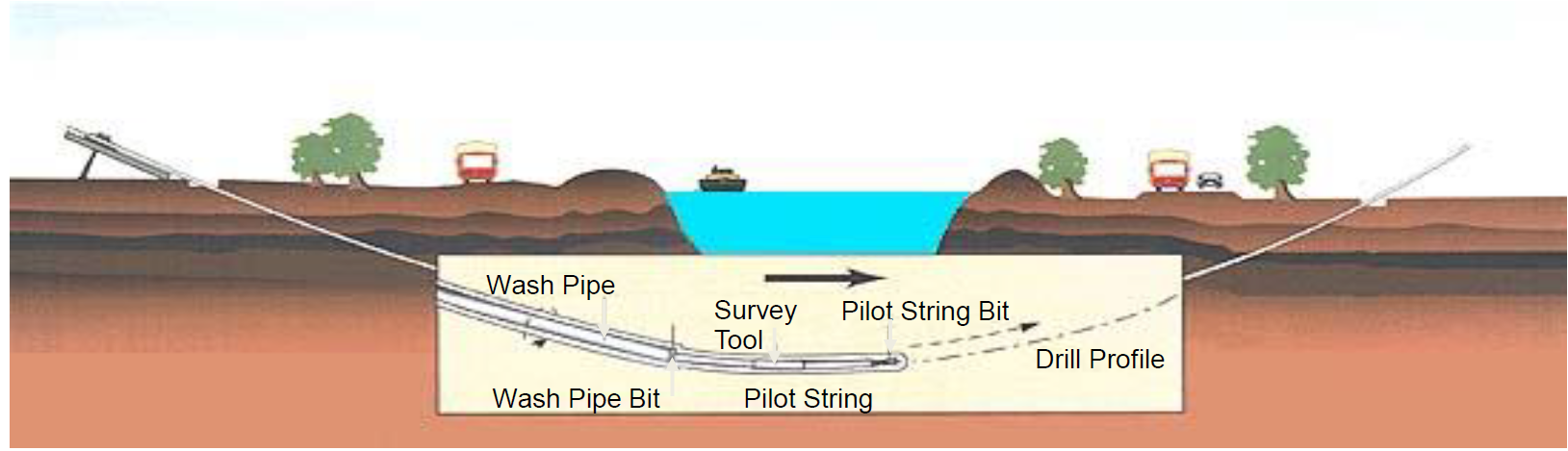

Step 1: Drill/Bore the Pilot Hole

Step one involves the use of a pilot bit to create a borehole.

- To ensure the drill path is created without encountering unforeseen obstructions, set up the HDD equipment and begin drilling a pilot hole.

- Various steerable drill heads are used based on soil type.

- Walk-over or wireline type navigation should be used during drilling.

- The pilot hole is generally smaller in diameter than the final borehole, typically 4 inches in diameter.

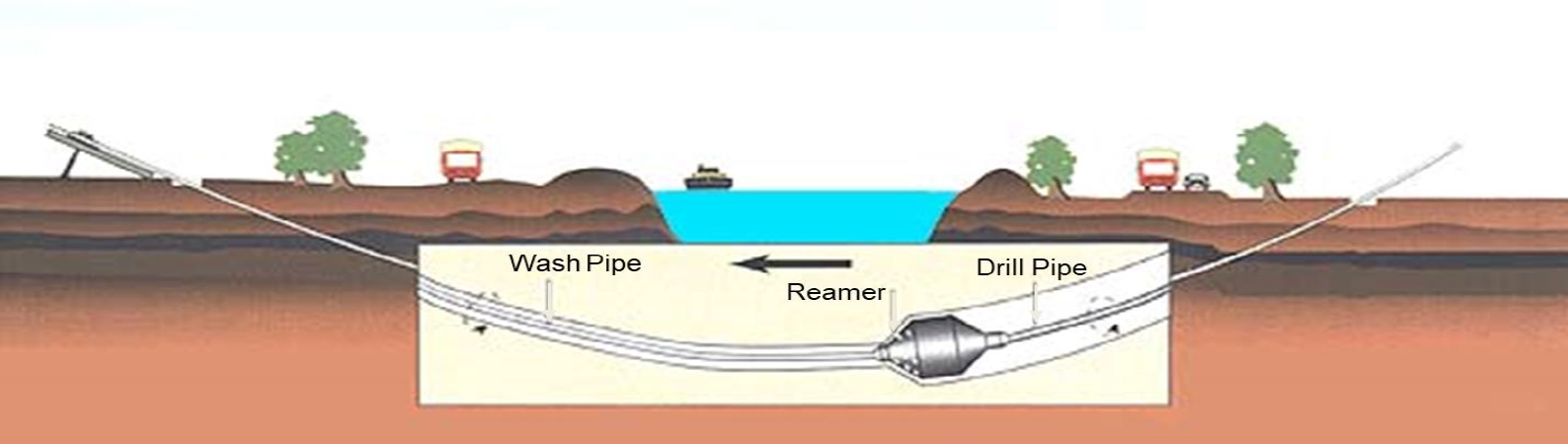

Step 2: Pre-Ream

- After drilling the pilot hole, the process of pre-reaming should begin.

- Pre-reaming is simply enlarging the pilot hole to the proper size to pull the new pipe material through the borehole.

- Pre-reaming may take one to several passes with progressively larger reamers to reach the final drill path size.

Step 3: Establish a Drill Path Diameter

-

Typically, the final drill path diameter is 1.5 times larger than the largest outside diameter of the pipe. A pipe outside diameter vs. bore size calculator is available using McWane’s Pocket Engineer.

- For example, if the largest outside diameter of the pipe is 16 inches, then your final drill path diameter is approximately 24 inches.

- After the final drill path diameter is achieved, the pipe installation can begin.

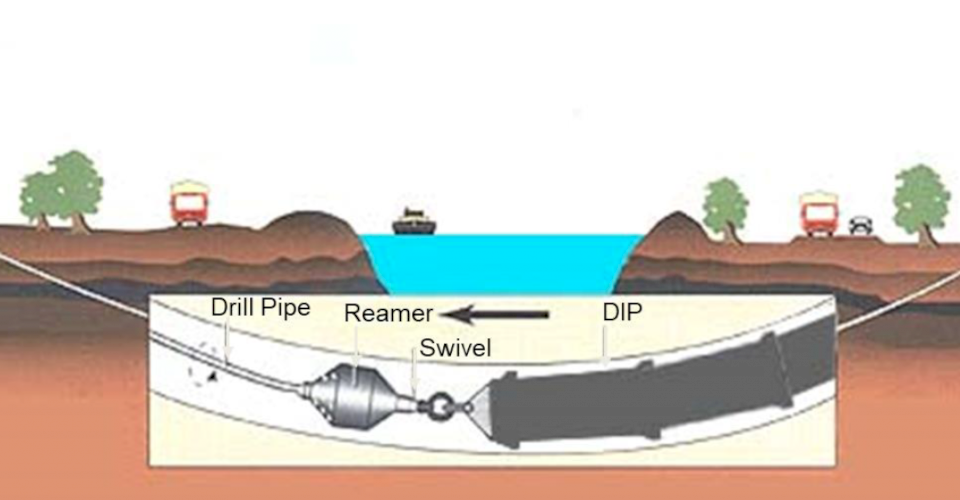

Step 4: Install Ductile Iron Pipe

- Pipe installation is achieved by the "pull-back” of the product pipe from a drill rig.

- During the pull-back process, a drilling fluid (typically a Bentonite slurry) should be introduced to the drill path to help reduce friction.

- A rotating reamer should be used to maintain a clear and open drill path during the pipe pull-back process.

- A swivel should be used to attach the reamer to the product pipe.

How Big Is Your Rig? – Pulling Force Considerations

Often, we are asked what pulling forces are required for an HDD project, or how many feet can be pulled at one time. One of our most common responses is: "How big is your rig?" This response is primarily due to the durability of Ductile iron.

Seriously, there are many factors to consider. The weight of the entire pipe length is the best general factor to use when calculating the pulling force requirement. Keep in mind that when a slurry is used, the DI pipe tends to be neutrally buoyant and will not float to the top or sink, reducing the pulling force required.

The opposite holds for alternative products, such as PVC or HDPE. These materials tend to float along the top of the drill hole, increasing pressure and drag along the entire length of the bore and ultimately increasing the pulling force requirement. In addition, most alternate materials require scratches or gouging to be no more than 10 percent of the pipe's diameter to pass inspection.

Think of a Ductile iron system like links in a chain. All the "links" are free-floating and follow the direction of the leading link. Let's examine a practical example of a project that was completed in Mobile, Alabama, by Gator Boring.

The project consisted of 2800 linear feet of 12-inch Class 52 TR FLEX® pipe pulled through a casing, using a 440 American Auger boring machine. The estimated weight of the pipe was 128,000 pounds, and the rated pulling force of the 440 American Auger is 440,000 thrust/pull-back.

Don’t Get Stuck in the Mud - Considerations for Bentonite Clay

To reduce friction and pulling forces, Bentonite Clay is often mixed with fresh water to create a slurry or mud. This is particularly true in coarse soil conditions. However, the use of Bentonite slurry may not be required for loose or sandy soils.

The drill slurry has a density very similar to that of DI pipe. This allows the pipe to sit in the middle of the drill hole, reducing friction during the pipe pull-back and requiring less energy from the drill rig.

Time is Money – Installation Considerations

Cartridge and Assembled Line are the two methods of installing TR FLEX® pipe in an HDD application.

The Cartridge Method involves installing pipes one at a time during the pull. This type of pull dramatically reduces the amount of space required to complete the project. The time required to assemble the TR FLEX® joint is often equivalent to the time needed to change the drill rod sections used by the boring machine.

A crew working as a team can be extremely efficient compared to alternative product installations. Specifically, alternate product installations can take up to one hour to fuse and cool a single joint before pulling.

Conversely, making an 8-inch TR FLEX® joint may take as little as one minute. DI pipe is often installed in a wide range of weather conditions as well. I have yet to see a contractor wait for a lovely sunny day and a half-mile of real estate to install DI pipe for a bore. However, I have certainly seen such limitations with some alternative materials.

The Assembled Line Method involves pipes installed above ground and pulled into one section. The subsequent line may be laid out on the ground or rollers if desired.

Puller heads are available in all sizes to ease installation. The puller head assembles to the spigot end of the pipe in the same manner as a TR FLEX® Joint.

A connection is made between the puller head and the drill piping using a clevis. Then the pipe is pulled back through the bore. It is important to remember that the pipe must be pulled spigot-end-first due to the contour of the bell.

Wrap it Up – Corrosion Protection Considerations

Installation of V-BIO polyethylene encasement may be required for the project. Soil samples and conditions should be considered before selecting any corrosion protection for DI pipe. If required, ANSI/AWWA C105-A21 “Alternate Method A for Wet Trench Conditions” installation guidelines should be followed.

Does the Polyethylene Encasement remain on the pipe throughout the bore? In this author's experience, it certainly does. I've witnessed the encasement remain intact during installation with a bentonite slurry.

Also, keep in mind that McWane Ductile provides on-site technical assistance and/or training, upon request, typically at no additional cost.

In Conclusion, DI Pipe is a Great Material Option for HDD

Ductile iron pipe is well-suited for HDD for the following reasons:

- When there is not enough room on the job site for a lay-down area for the fusion pipe.

- When alternate pipe materials must be fused together for the entire drill length, requiring a larger staging area. Most drill projects pull all the drill pipe at once.

- DI pipe can be assembled and pulled all at once if enough area is available for the project.

- DI pipe can be assembled using the Cartridge Method if the project is in a congested area, such as a city.

- The effect of scratches on DI pipe is less traumatic than on alternative materials.

- Sun exposure and UV rays do not degrade DI pipe while stored on the job site.

- DI pipe does not require fusion-welded joints that create “speed bumps,” as experienced when using alternate materials.

- Surge Allowance is included in DI pipe design.

- Future connections on DI pipe do not require specialized coatings or specialized fusion equipment.

Ductile iron pipe is an excellent piping system for HDD projects. It is a durable material, easy to install, and offers the largest inside diameter on the market. If you have any questions regarding using DI pipe for Horizontal Directional Drilling, please contact your local McWane Ductile representative. We also offer on-site technical services from engineers who are glad to assist with the design, facilitation, and completion of your HDD project. McWane Ductile – Building Iron Strong Utilities For Generations!

Be sure to check out all our digital offerings: