-

V-Bio® Or Cathodic Protection – An Honest Comparison

12/13/2019 In Installation Products TechnicalOdds are you may not be a certified corrosion specialist or an expert in the corrosion field for that matter. Most engineers that are responsible for specifying water projects are not. There are of course engineers who dedicate their entire careers to the subject. The good news is that McWane Ductile is committed to excellence in the corrosion field and provides professionals to assist you with making sound decisions regarding corrosion control.

-

Why Zinc on Ductile Iron Pipe and What's the Hype?

10/10/2019 In Installation Products TechnicalOver the past several years, you may have heard a lot about applying zinc to your Ductile iron pipe as either a means of corrosion protection or as an added product which will extend the life of DI pipe in a non-corrosive environment. In this blog, we will look a bit closer at the origin of the practice and effectiveness of using zinc for external corrosion protection.

-

Three Common Questions About Ductile Iron Pipe Gaskets

09/19/2019 In Installation ProductsIt is very common to get certain questions from our customers regarding the interchangeability of push-on or compression type gaskets that are typically supplied with Ductile iron pipe. These questions are usually easy to answer in a very definitive manner, but there are some exceptions. In this edition of Iron Strong, we will address the three most common questions about gaskets and why this can sometimes be confusing to our customers.

-

What is the Purpose of the Seal Coat on Ductile Iron Pipe?

07/20/2019 In Products TechnicalThe normal, stocking item for Ductile iron pipe products is lined and coated with a sealcoat that comes in your choice of black. Many water professionals wonder about the purpose of this coating, or paint, that gives Ductile iron pipe it’s familiar appearance. In this article we offer some explanation and history behind the application and advancement of the sealcoat.

-

How Is Ductile Iron Pipe Made?

07/02/2019 In Our Company ProductsVisitors who tour a McWane Ductile facility are often surprised by how much work goes into making Ductile iron pipe. The pipe starts out as scrap metal from old cars and demolished buildings that is melted down and given a new lease on life. Up to 95% of our product is made from recycled material.

Once this metal is in its molten state a crane carries it to centrifugal casting machines where it is spun into a pipe. Next it heads to the annealing oven, an important step in transforming the iron into ductile.

-

Proper Gasket Storage and Care

06/27/2019 In Products TechnicalGaskets are a critical component in your ductile iron piping system. To get the full benefit of your gaskets, they need to be stored in a manner that minimizes deterioration. We don’t always work in favorable conditions, so no matter if you are in the field or in a warehouse, utilizing the best storage practices and locations are key to the performance and the effective lifetime of your gaskets.

In this article, we will cover some guidelines on how to store and care for your gaskets. We will cover the “what to do” as well as the equally important,”what not to do.”

-

How Much Does Ductile Iron Pipe Cost?

05/31/2019 In Products TechnicalIt is pretty much a daily occurrence here at McWane Ductile for our sales staff to receive price requests on a variety of ductile iron pipe (DI pipe) products. Usually this request is for a specific project, but occasionally design engineers will also ask for “budget pricing” for future underground utility projects. This is typically a pretty simple task, but to provide the most accurate and cost-effective pricing, there are a few items that must be addressed that will ultimately determine the final cost to the customer. This article will review some of those variables that determine the final pricing for your DI pipe needs.

-

Corrosion Protection Recommendations for Ductile Iron Pipeline

05/10/2019 In Products TechnicalDuctile iron pipe (DIP) is one of the most widely used pipe materials in North America. The Design Life is second to no other pipe material due to its robust design. This pipe material is the strongest and most resilient available for water and wastewater utilities providing unparalleled Life-Cycle value.

In many areas, utilities need to consider how to protect these valuable pipelines from corrosive soils. The question is “How can we economically protect these pipelines to meet or exceed the 105-110 year average design life of DIP?”

-

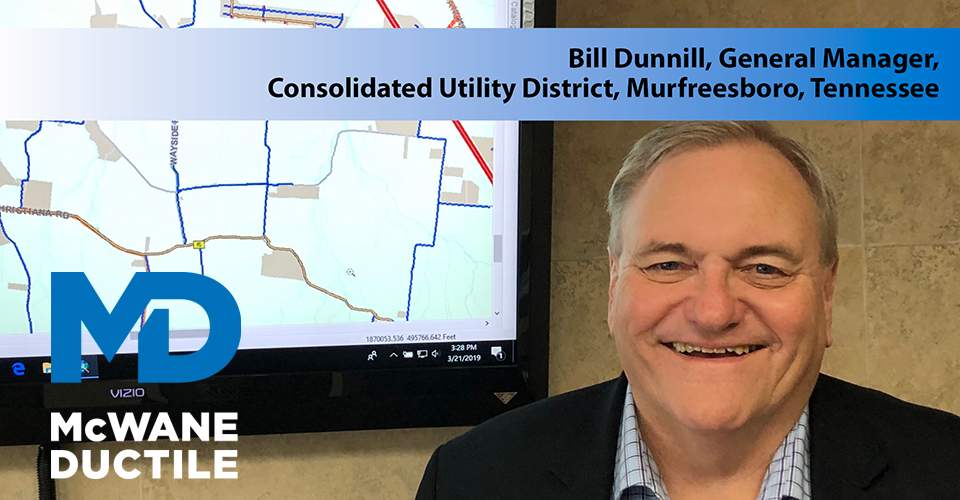

Why Use Ductile Iron Pipe? An Interview With Bill Dunnill, GM, Consolidated Utility District

05/03/2019 In Products TechnicalEven in this modern era, we are still concerned with many of the issues that early civilizations faced when providing water to our communities, such as supply and demand, pipeline construction and upkeep, cleanliness, conservation and cost. In the fall of 2018, McWane Ductile’s Senior Regional Engineer, Roy Mundy, had the opportunity to interview Consolidated Utility District General Manager Bill Dunnill. The two gentlemen, both with utility management experience, had a candid conversation about Bill’s day-to-day challenges, successes and his preferred choice of pipeline material. The following are excerpts from their discussion.

-

How to Repair Protecto 401™ Lining in The Field

04/18/2019 In Products TechnicalWhen talking about ductile iron pipe in sewer applications, many times Induron’s Protecto 401™ comes to mind. Protecto 401 lining has often been the specified lining for ductile iron pipe in sewer applications more than 50 years.

Common uses for Protecto 401 are for a sewer force main that may not be fully running, where trapped air may exist, where chemical resistance is required, or for abrasion resistance. There may be occasions in the field when patching of the Protecto 401 lining may be necessary.

Latest Posts

- The Future Is Now: How the Water Industry Is Revolutionizing 01/29/2026 In Products Technical Technology Training

- What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe? 01/28/2026 In Products Technical

- How to Repair Ceramawrap Coating on Ductile Iron Pipe in the Field 01/28/2026 In How To Products Technical

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry