-

Proper Gasket Storage and Care

06/27/2019 In Products TechnicalGaskets are a critical component in your ductile iron piping system. To get the full benefit of your gaskets, they need to be stored in a manner that minimizes deterioration. We don’t always work in favorable conditions, so no matter if you are in the field or in a warehouse, utilizing the best storage practices and locations are key to the performance and the effective lifetime of your gaskets.

In this article, we will cover some guidelines on how to store and care for your gaskets. We will cover the “what to do” as well as the equally important,”what not to do.”

-

How Much Does Ductile Iron Pipe Cost?

05/31/2019 In Products TechnicalIt is pretty much a daily occurrence here at McWane Ductile for our sales staff to receive price requests on a variety of ductile iron pipe (DI pipe) products. Usually this request is for a specific project, but occasionally design engineers will also ask for “budget pricing” for future underground utility projects. This is typically a pretty simple task, but to provide the most accurate and cost-effective pricing, there are a few items that must be addressed that will ultimately determine the final cost to the customer. This article will review some of those variables that determine the final pricing for your DI pipe needs.

-

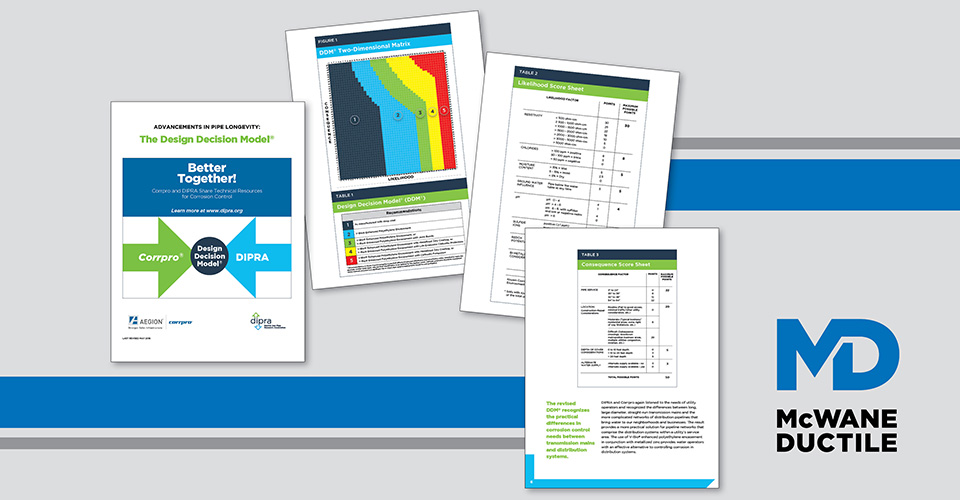

Corrosion Protection Recommendations for Ductile Iron Pipeline

05/10/2019 In Products TechnicalDuctile iron pipe (DIP) is one of the most widely used pipe materials in North America. The Design Life is second to no other pipe material due to its robust design. This pipe material is the strongest and most resilient available for water and wastewater utilities providing unparalleled Life-Cycle value.

In many areas, utilities need to consider how to protect these valuable pipelines from corrosive soils. The question is “How can we economically protect these pipelines to meet or exceed the 105-110 year average design life of DIP?”

-

Why Use Ductile Iron Pipe? An Interview With Bill Dunnill, GM, Consolidated Utility District

05/03/2019 In Products TechnicalEven in this modern era, we are still concerned with many of the issues that early civilizations faced when providing water to our communities, such as supply and demand, pipeline construction and upkeep, cleanliness, conservation and cost. In the fall of 2018, McWane Ductile’s Senior Regional Engineer, Roy Mundy, had the opportunity to interview Consolidated Utility District General Manager Bill Dunnill. The two gentlemen, both with utility management experience, had a candid conversation about Bill’s day-to-day challenges, successes and his preferred choice of pipeline material. The following are excerpts from their discussion.

-

Using The Preliminary Engineering Report (PER) In Funding Requests

04/30/2019 In TechnicalToday there are several funding methods and sources for water and wastewater projects, not only in the United States but throughout the world. Most, if not all, require some sort of report or project summary. You may have seen these with such names as Conceptual Design or Engineering Report, Facilities Needs Assessment, Preliminary Design Report, Preliminary Engineering Report. Different agencies and different countries have different names for these respective documents, but most are like each other in scope and requirements.

-

How to Repair Protecto 401™ Lining in The Field

04/18/2019 In Products TechnicalWhen talking about ductile iron pipe in sewer applications, many times Induron’s Protecto 401™ comes to mind. Protecto 401 lining has often been the specified lining for ductile iron pipe in sewer applications more than 50 years.

Common uses for Protecto 401 are for a sewer force main that may not be fully running, where trapped air may exist, where chemical resistance is required, or for abrasion resistance. There may be occasions in the field when patching of the Protecto 401 lining may be necessary.

-

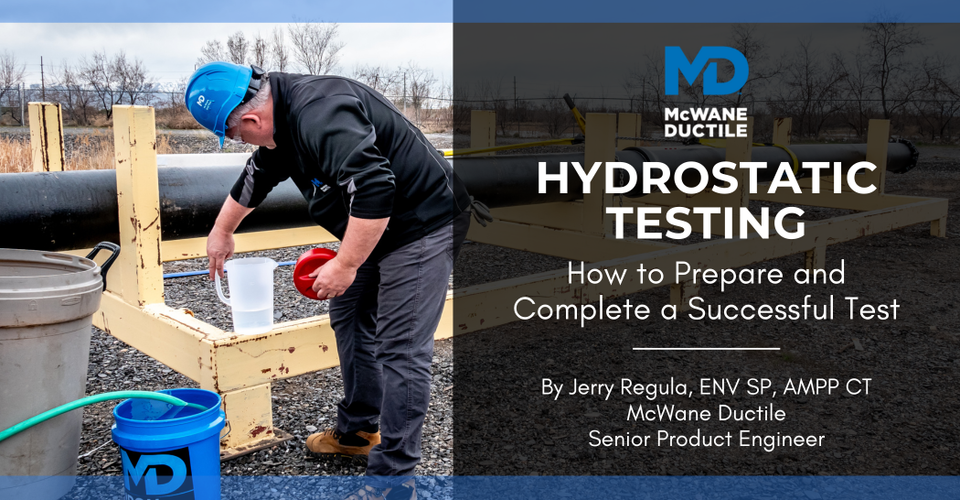

How to Successfully Prepare and Complete a Hydrostatic Test

04/12/2019 In Services TechnicalPicture This

Much time, effort, and care have gone into installing a water line. Crews have worked through inclement weather. Unexpected rock was found, slowing progress but not stopping the pipe's installation. Crews have worked long hours to meet deadlines and are anticipating the end of the project.

But wait, you have not pressurized the line. All eyes are on that gauge, hoping to validate that the work was successfully completed.

-

The 18-Inch Transmission Main Story

04/05/2019 In Products Technical“It was a normal day on the job while working for the city of Hayward, California. Later that morning, I got word that an earth moving contractor hit our transmission main. My stomach turned because it is one of two feeds that supplies water all the way up the hills of Hayward in a series of 250-foot lifts (elevation gains)…”

The following article was recently featured in McWane Ductile’s Modern McWane magazine and tells of one water professional’s experience when faced with what could have been a catastrophic event, and the decisions he made to resolve a very large pipeline problem.

-

Why Use V-Bio® Polyethylene Instead of Standard Polyethylene Tubing?

03/09/2019 In Products TechnicalThe more than 75 years of ongoing research on iron pipe corrosion and the use of polyethylene encasement has led to this type of corrosion mediation becoming the accepted industry practice for protecting ductile iron pipe. So, the question many may ask is; “Since I had such success with standard polyethylene encasement, why should I now use V-Bio Polyethylene Encasement instead?” To best answer this, it’s imperative to look at what specifically V-Bio provides that is not available with standard polyethylene encasement.

-

Why Should I Use Ductile Iron Pipe? Four Key Considerations

02/28/2019 In Environmental & Safety Installation Technical“Why should I use Ductile iron pipe?”

The question is ostensibly meant to include “instead of other types of piping material.” Well, the reasons are vast and vary depending on project requirements. Since we aren’t talking about a specific project, we’ll look at the general overriding reasons Ductile iron pipe is the best choice for your piping projects.

Latest Posts

- Can Joining Water Works Industry Organizations Help You Grow Professionally? 10/21/2025 In Careers WaterWorks

- How Does Ductile Iron Pipe Provide Proven Resilience to Seismic Events? 09/04/2025 In Products Resiliency Technical

- How to Secure Green Reserve Sustainability Incentives Using State Revolving Funding & Ductile Iron Pipe 07/29/2025 In Energy Products Technical

- UPDATED - Ductile Iron Pipe Versus HDPE - A Comparative Narrative 05/29/2025 In Comparisons Products Technical