-

How to Properly Unload, Store and Install Ductile Iron Outlet Pipe

08/03/2019 In Installation TechnicalRadial Welded-on Outlets, Tangential Outlets, Bossed Outlets, and Thread-O-Lets. Have you ever been involved in a project utilizing one of the various pipe outlet configurations? If so, you are likely aware of the special care these products require. If you haven’t been involved in a project requiring outlet piping, then within this blog we will explain the types of outlets available and the importance of the unloading, storage, and installation process.

-

How Can I Connect Other Materials to Ductile Iron Pipe?

07/31/2019 In Installation TechnicalDuctile Iron (DI pipe) was first used in the United States as early as 1950's. Since iron pipe was one of the earliest pipe materials to be used in modern water works and wastewater systems, most early fittings and couplings were designed to be used on Grey Cast and then Ductile iron pipe.

So, connecting “other” piping material to DI pipe is very straightforward on the Ductile pipe side of the fitting. The most important item to consider is on the other material side of the connection.

-

Why Should I Use Ductile Iron Pipe? Four Key Considerations

02/28/2019 In Environmental & Safety Installation Technical“Why should I use Ductile iron pipe?”

The question is ostensibly meant to include “instead of other types of piping material.” Well, the reasons are vast and vary depending on project requirements. Since we aren’t talking about a specific project, we’ll look at the general overriding reasons Ductile iron pipe is the best choice for your piping projects.

-

TR Flex® Versus Mechanical Joint - Why TR Flex® Fittings Are The Smart Choice

01/22/2019 In Installation Products TechnicalWhen designing or constructing ductile iron pipe utility projects, there is often a discussion of about what joint to use for restraint at the fittings - TR Flex® fittings or the more common Mechanical Joint (MJ) fitting with retainer glands?

As a contractor or engineer, what is important to you? Time, flexibility, or cost? Let me guess, you want all three. Below we will look at some of the items to consider that may assist you in this decision.

-

Does McWane Ductile Offer Product Training?

12/21/2018 In Installation Products Services TechnicalMcWane Ductile offers multiple services for our customers extending far beyond manufacturing ductile iron pipe. From design to installation, we take great pride in providing education to water professionals throughout the water industry.

-

Sure Stop 350® Gaskets vs TR Flex® Pipe: Which Restraint is Best?

09/25/2018 In Installation Products TechnicalThere are several methods for restraining Ductile Iron Pipe joints, and a common question from our customers is, “Which method of restraint is best—locking gaskets or boltless restrained joints?” Both methods are effective, but the best choice for your project depends on the type of installation, the operating pressure of the line, and the diameter of the Ductile iron pipe being used. In this #IronStrong Blog, we will compare two common restraint options offered by McWane Ductile: Sure Stop 350® Gaskets and TR Flex® Pipe.

-

How Do Spigot Stripes Assist in the Assembly of Ductile Iron Pipe?

06/22/2018 In InstallationSpigot stripes are used as a guide for assembly and a deflection check after assembly. Pipelines are not always designed in a straight line. It is often necessary to deflect pipe from a straight line to follow the curvature of streets and roads both vertically and horizontally. Ductile iron pipe is well suited for joint deflection.

-

What is TR Flex® Pipe and How is it Assembled?

06/08/2018 In Installation ProductsTR Flex® is the most widely accepted and installed integrally cast restraint joint system in the Ductile iron pipe industry. Proven as a versatile and easy-to-use item, this joint is flexible, sure, and watertight to and beyond its up-to-350-psi pressure rating while preventing longitudinal separation of the joints, whether installed above or below ground.

-

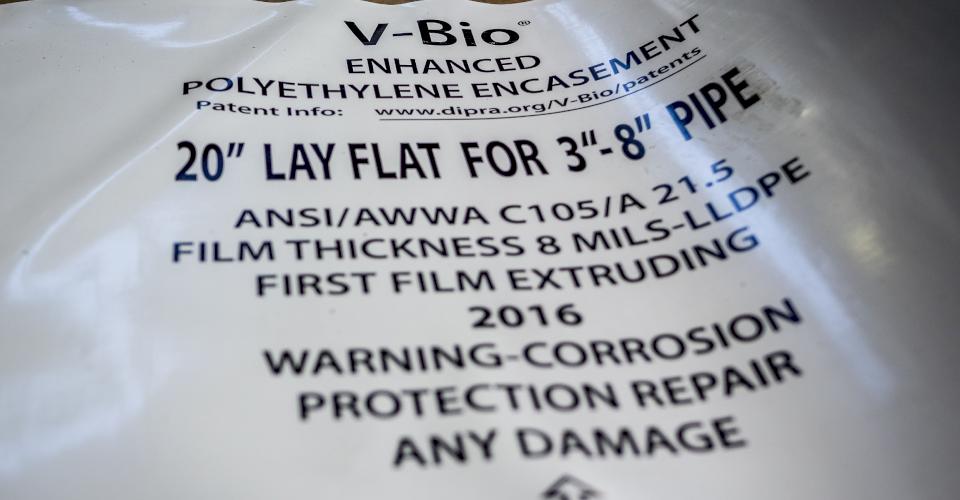

Eight Steps for Installing V-Bio® Polywrap (With Video)

04/06/2018 In InstallationPolyethylene encasement (polywrap) has been used since 1958 to protect ductile iron pipe from corrosion. It is the most popular, economical, and successful method for protecting pipe from corrosion.

A new advancement in polyethylene encasement called V-Bio® adds additional protection by inhibiting the formation of corrosion cells under the wrap. McWane Ductile added V-Bio® polywrap to its line of products in 2015. Adding a few steps to your pipe installation with V-Bio® is an Iron Strong decision that will benefit your pipeline for generations.

Latest Posts

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry

- Can Joining Water Works Industry Organizations Help You Grow Professionally? 10/21/2025 In Careers WaterWorks

- How Does Ductile Iron Pipe Provide Proven Resilience to Seismic Events? 09/04/2025 In Products Resiliency Technical

- How to Secure Green Reserve Sustainability Incentives Using State Revolving Funding & Ductile Iron Pipe 07/29/2025 In Energy Products Technical