-

What Does Diversity Look Like in the Manufacturing Industry?

03/08/2022 In Our CompanyOver the years, manufacturing companies have not made as much progress with diversity and inclusion – specifically in recruiting women – like other sectors, but by working together and sharing best practices, we can become more effective in this initiative.

-

Ask the Ditch Doctor - Does Internal Pressure Always Govern Ductile Iron Pipeline Design?

03/04/2022 In Ditch Doctor Installation TechnicalHave you ever been so taken aback by the structure of a question that your first thought is, “say what? Did they really just ask me that?” In the vernacular-sensitive world of utility pipelines, it happens more often than you might think.

-

How Do Engineers Impact the Waterworks Industry?

02/26/2022 In Our Company ProductsIt’s National Engineers Week (EWeek). Founded by the National Society of Professional Engineers in 1951, (EWeek) is dedicated to promoting careers in engineering and technology to develop a diverse and well-educated future engineering workforce. This #IronStrong Blog spotlights the importance of engineers and how they impact the waterworks industry.

-

Why Doesn’t McWane Ductile Make Large Diameter Locking Gaskets?

02/11/2022 In Products TechnicalLocking gaskets are the industry standard for dependable, reliable, and easy installation of Ductile iron pipe (DI pipe) in 3-inch through 24-inch diameters. Locking gaskets for DI pipe have been around for more than 30 years and have been used in over one million push joint installations. However, as good as locking gaskets are in 3-inch through 24-inch, there were challenges involved when attempting to install in 30-inch and 36-inch diameter pipe. In this Iron Strong Blog, we will look at the various reason we do not make large-diameter locking gaskets for DI pipe.

-

How to Uninstall Ductile Iron Pipe Joints that Contain Locking Gaskets

01/27/2022 In Installation Products TechnicalHave you ever been on a Ductile iron pipe (DI pipe) installation with restrained joint gaskets and needed to uninstall a previously assembled joint? This is normally prompted by the need to replace a displaced or a “pinched” gasket. Proper gasket placement and attention during assembly is the best way to avoid such conditions, as detailed in a previous blog by McWane Ductile. Unfortunately, the problem often does not arise until the pipeline is hydrostatically tested. In today’s Iron Strong Blog, we will examine the “Dos & Don'ts" of uninstalling with DI pipe restrained joint gaskets.

-

What Trenching and Excavation Guidelines are Important when Installing Ductile Iron Pipe?

01/07/2022 In Environmental & Safety InstallationHave you ever been asked what size trench is needed when installing Ductile iron pipe (DI pipe)? How safe are the working conditions within a trench? Knowing the proper trench to utilize during the installation of the material will help save time, effort, and money on any job site. But most importantly, this knowledge will help keep everyone safe within and around the trench. The Occupational Health and Safety Administration (OSHA) has gone to great lengths to define and identify any threats in the trenching and excavation safety when installing DI pipe. This Iron Strong Blog will share and explain the different trenches available while outlining the safety considerations required when excavating earthen material.

-

What Are the Three Pipe Tapping Methods?

12/27/2021 In Products TechnicalSo, you have an existing water distribution system feeding a small hospital and a military post. Now you need to branch off the pipeline to feed another 30 new houses under construction nearby. How do you do it without interrupting service to the critical facilities already being served? In this Iron Strong Blog, we’ll discuss three common pipe tapping methods used in the water and wastewater industry and the variables to consider when choosing the best method for your waterworks project.

-

Why Are Thrust Restraints Not the Same for All Pipe Materials?

12/13/2021 In Products TechnicalIn today’s marketplace, everything is in constant flux. Projects have specific completion times, and material lead times are continually increasing. For a variety of reasons, materials that typically were in stock for immediate shipment now take weeks to months before they are available to ship. You may be considering changing the piping material to be used in your water line project to another type of material. A significant consideration is how each type of piping material requires different lengths of restraint to control the change of direction in the line.

-

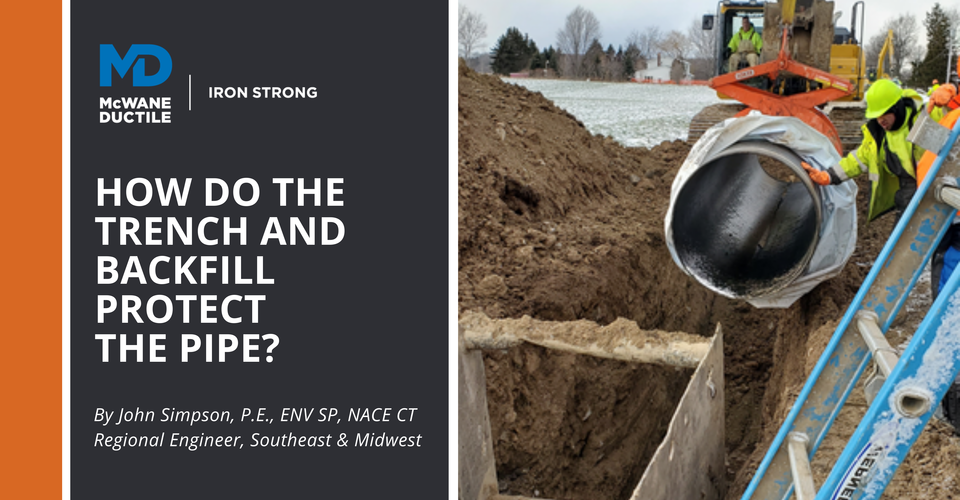

How Do the Trench and Backfill Protect the Pipe?

12/02/2021 In Installation TechnicalUtility pipelines provide for some of the most basic needs within our society. Essential services, such as supplying potable drinking water to our homes and businesses or sending wastewater away, are possible because of a network of buried pipelines. Whatever pipeline materials are used, they are expected to meet minimum service qualities such as withstanding leakage. This resiliency to leakage eliminates waste of our precious drinking water and prevents polluted soils from wastewater in the pipeline's proximity.

-

Why Is Using the Right Design Criteria Important in Calculating Restraint Requirements?

11/19/2021 In Installation TechnicalWhen I first started my engineering career, I was placed in charge of coordinating the relocation of water transmission and distribution pipelines to accommodate the construction of an interstate highway through a city of approximately 180,000 residents. Many times, these projects required pre-poured thrust block restraints due to the amended connections between new and old waterlines in a short timeframe so as not to leave customers inordinately out of water for long periods of time.

Latest Posts

- The Future Is Now: How the Water Industry Is Revolutionizing 01/29/2026 In Products Technical Technology Training

- What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe? 01/28/2026 In Products Technical

- How to Repair Ceramawrap Coating on Ductile Iron Pipe in the Field 01/28/2026 In How To Products Technical

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry