-

Using The Preliminary Engineering Report (PER) In Funding Requests

04/30/2019 In TechnicalToday there are several funding methods and sources for water and wastewater projects, not only in the United States but throughout the world. Most, if not all, require some sort of report or project summary. You may have seen these with such names as Conceptual Design or Engineering Report, Facilities Needs Assessment, Preliminary Design Report, Preliminary Engineering Report. Different agencies and different countries have different names for these respective documents, but most are like each other in scope and requirements.

-

How to Repair Protecto 401™ Lining in The Field

04/18/2019 In Products TechnicalWhen talking about ductile iron pipe in sewer applications, many times Induron’s Protecto 401™ comes to mind. Protecto 401 lining has often been the specified lining for ductile iron pipe in sewer applications more than 50 years.

Common uses for Protecto 401 are for a sewer force main that may not be fully running, where trapped air may exist, where chemical resistance is required, or for abrasion resistance. There may be occasions in the field when patching of the Protecto 401 lining may be necessary.

-

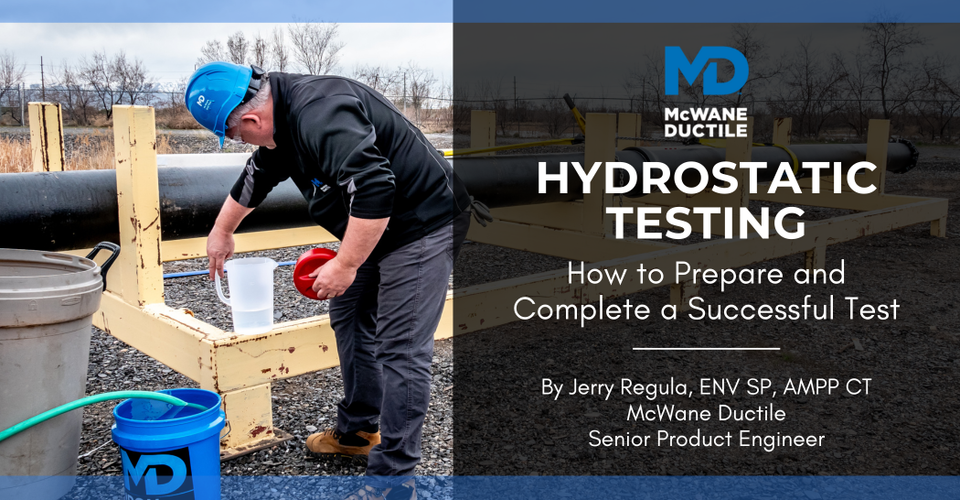

How to Successfully Prepare and Complete a Hydrostatic Test

04/12/2019 In Services TechnicalPicture This

Much time, effort, and care have gone into installing a water line. Crews have worked through inclement weather. Unexpected rock was found, slowing progress but not stopping the pipe's installation. Crews have worked long hours to meet deadlines and are anticipating the end of the project.

But wait, you have not pressurized the line. All eyes are on that gauge, hoping to validate that the work was successfully completed.

-

The 18-Inch Transmission Main Story

04/05/2019 In Products Technical“It was a normal day on the job while working for the city of Hayward, California. Later that morning, I got word that an earth moving contractor hit our transmission main. My stomach turned because it is one of two feeds that supplies water all the way up the hills of Hayward in a series of 250-foot lifts (elevation gains)…”

The following article was recently featured in McWane Ductile’s Modern McWane magazine and tells of one water professional’s experience when faced with what could have been a catastrophic event, and the decisions he made to resolve a very large pipeline problem.

-

How McWane Ductile Fabricates Pipe to Suit Your Plant Job

03/29/2019 In Our Company Products ServicesAs a general or mechanical contractor, you want to know the piping materials for your job are fabricated to meet or exceed project specifications and delivered in a timely manner. McWane Ductile-Ohio has a dedicated Treatment Plant Division providing specialized Design-Build services to support your project from concept to final buildout. Our team provides pre- and post-bid services to ensure your projects are completed on time and on budget.

-

What Is The Recycled Content Of Ductile Iron Pipe and Why Is It Important?

03/22/2019 In Environmental & Safety ProductsIn today’s world, we all recognize the need to be concerned with our environment and natural resources. We all realize that these things are limited and not self-restoring. We now have several generations that have always had recycling and environmental awareness in their lives. This post drills deeper into the question What is the Recycled Content of Ductile Iron Pipe and Why Is It Important?

-

Why Use V-Bio® Polyethylene Instead of Standard Polyethylene Tubing?

03/09/2019 In Products TechnicalThe more than 75 years of ongoing research on iron pipe corrosion and the use of polyethylene encasement has led to this type of corrosion mediation becoming the accepted industry practice for protecting ductile iron pipe. So, the question many may ask is; “Since I had such success with standard polyethylene encasement, why should I now use V-Bio Polyethylene Encasement instead?” To best answer this, it’s imperative to look at what specifically V-Bio provides that is not available with standard polyethylene encasement.

-

Why Should I Use Ductile Iron Pipe? Four Key Considerations

02/28/2019 In Environmental & Safety Installation Technical“Why should I use Ductile iron pipe?”

The question is ostensibly meant to include “instead of other types of piping material.” Well, the reasons are vast and vary depending on project requirements. Since we aren’t talking about a specific project, we’ll look at the general overriding reasons Ductile iron pipe is the best choice for your piping projects.

-

Can McWane Ductile Provide Bonded Coatings?

02/21/2019 In Products Services TechnicalCan McWane Ductile provide bonded coatings? A good question recently posed and more frequently asked due to a greater recognition of potential corrosive environments. To correctly address this question, some other questions need to be answered first.

-

To DBE or Not to DBE…

02/14/2019 In Services TechnicalIf your company provides any goods or services to a governmental entity, such as the Small Business Administration (SBA), Department of Transportation (DOT), or Environmental Protection Agency (EPA), and similar state agencies and municipalities, you may be familiar with requirements to have a percentage of the work performed by Disadvantaged Business Enterprises (DBEs). Many federal, state, and local entities have passed laws and regulations to encourage the use of DBEs in government contracts.

Latest Posts

- The Future Is Now: How the Water Industry Is Revolutionizing 01/29/2026 In Products Technical Technology Training

- What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe? 01/28/2026 In Products Technical

- How to Repair Ceramawrap Coating on Ductile Iron Pipe in the Field 01/28/2026 In How To Products Technical

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry